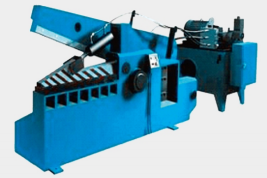

Cold Mill Aluminium Foil Aluminium Coil Ukwenza Umshini Wokwenza

| Le yindawo ka Origin | I-Guangxi, China | Amandla | 500-10000 |

| I gama le-brand | I-Runxiang | Ubukhulu(L*W*H) | 1.7*1.3*1.5 |

| Uhlobo | I-Hot Rolling Mill | Iwaranti | 1 Unyaka |

| Isimo | Okusha | Amaphuzu Okuthengisa Abalulekile | Ukukhiqiza Okuphezulu |

| Umbiko Wokuhlolwa Kwemishini | Kuhlinzekiwe | Izimboni Ezisebenzayo | Izitolo Zezinto Zokwakha, Imboni Yokukhiqiza, Izitolo, Imisebenzi Yokwakha |

| Uhlobo Lokumaketha | Umkhiqizo Omusha wango-2023 | Igama lomkhiqizo | I-Foil Rolling Mill |

| Iwaranti yezingxenye eziyinhloko | 1 Unyaka | Umbala | Noma yikuphi |

| Izingxenye Eziyinhloko | PLC, Injini, Gearbox, Motor, Gear | Okujwayelekile | Ukwenza ngokwezifiso |

| Amandla kagesi | 380V/6000V | Izinto eziluhlaza | Ukusakaza i-billet eqhubekayo |

I-aluminium foil roughing Mill ingumshini ogoqa ishidi le-aluminium futhi ukhumule amakhoyili anento engu-0.5mm noma ngaphansi ezindaweni ezimbalwa ukuze awenze abe ucwecwe lwe-aluminium engu-2×0.0045mm noma ngaphezulu ukujiya.

Ukwethulwa kwe-aluminiumi-foil rolling mill.

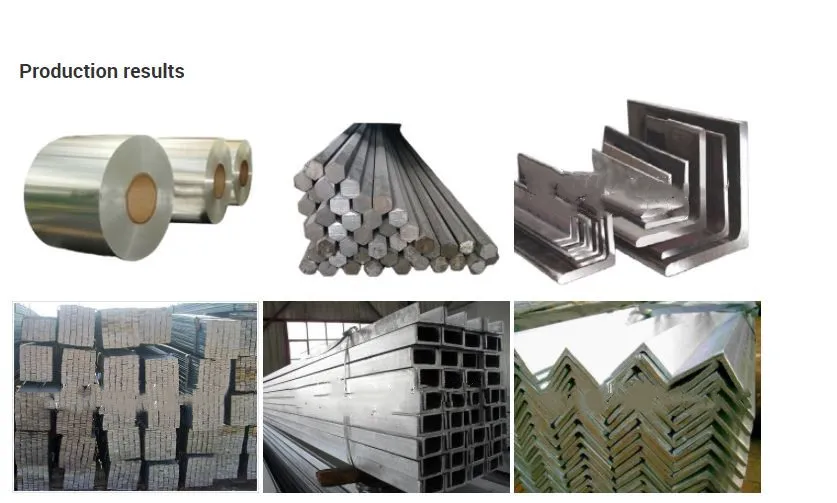

Isethi yemishini yemboni ye-aluminium kanye nemishini esetshenziselwa ikakhulukazi ukugingqa, ukucubungula nokucwengisiswa kwe-aluminium foil.

Ukusebenza namaphuzu abalulekile

Ukusebenza namaphuzu abalulekile

1. Ukulungiselela kusengaphambili

1.1 Hlola isimo sokusebenza sesistimu ngayinye ukuze uqinisekise

1.2 Shintsha amaroli ngokweshejuli kanye nokuhlola

a) Isimo se-nozzle, ukuvinjelwa

b) Qinisekisa indawo yomugqa ogoqayo

c) Ukuxhumana kwepayipi lenkungu kawoyela kufanele kube kuhle

1.3 Lungiselela futhi ulayishe impahla ngokohlelo futhi unake

a) Khipha ungqimba olungaphezulu ukuze uvimbele uthuli netheyiphu ukuthi ingangeni emshinini wokugaya ukuze uvimbele izimpawu zokugoqa

b) Qinisekisa ikhwalithi yobuso bokuphela komqulu?Imihuzuko ecijile emincane ephethwe ngendlela eyindilinga.

2. Inqubo yokusheshisa

2.1 Okusanda kushintshwa kwaba umqulu womsebenzi

2.1.1 Shisisa ama-rolls i-3~5min ngokwesimo esijwayelekile sokugijima kwe-roll;imiqulu evuthayo ingaba ngaphansi.

2.1.2 I-AFC ekulawuleni isilinganiso sesifutho sikawoyela wombhobho emkhawulweni ophansi wethebula lenqubo ingafinyelela ngokushesha ukuma kwepuleti elifanele ngemva kokululama.

2.1.3 Sebenzisa i-post-tension enkulu kunazo zonke kanye ne-pre-tension ukuze uzinze ngemva kokululama.

2.1.4 Sebenzisa amandla okugoqa afanele, amandla okugoqa, inani lokutsheka?Thembela kakhulu ekuqongeleleni kokuhlangenwe nakho okuvamile ukuze ugweme uhlangothi olulodwa oluxegayo, uhlangothi olulodwa oluqinile noma izinhlangothi zombili zixege kakhulu futhi ziqine kakhulu.

2.1.5 Sheshisa ngokushesha ngangokunokwenzeka ukuze ufinyelele ukujiya okuhlosiwe.

2.2 Inqubo yokugoqa evamile iyashesha

2.2.1 Ngokwenani lepharamitha ngayinye yamandla aginqikayo asethiwe asethiwe, agobayo, inani lokutsheka lingathola ukuma kwepuleti elibushelelezi.

2.2.2 Isivinini singanyuswa ngesinyathelo esisodwa ukuze singalungisi ipuleti ngaphambi kokuba ubukhulu obuqondiwe bube buncane kakhulu ubungako bokucindezela alikwazi ukusabalala.

2.3 Ukucutshungulwa kokushelela nokuvuleka kwe-seam ngesikhathi sokukhuphuka kusetshenzelweni lokuginqika izikhathi ezine.

2.3.1 Nciphisa isikhathi sokuguquguquka kwandisa amandla aginqikayo khulisa ukushuba kwangemuva okufanele ukukhulisa ukushuba kwangaphambili.

2.3.2 Thuthukisa izimo zokuthambisa usebenzisa izinga lokushisa eliphansi likawoyela elivulekile umthungo emafutheni okufuthwa ngokuvamile avuleka.

2.3.3 Noma kunjalo ayikwazi ukugoqwa lapho umqulu ushintsha.

3. Inqubo yokugoqa emaphakathi

3.1 Ukuqondanisa okuhle, ikakhulukazi impahla ebanzi izoveza uhlangothi oluxegayo kanye nohlangothi oluqinile, ngaleyo ndlela kubangele unqenqema oluqhekekile lombambo lwesibili oluxegayo kuthinte ukukhiqizwa okulandelayo.

3.2 I-AFC kufanele ihlale ilinganiswa amaroli ohlobo lwepuleti elinguziro esimweni sokusebenza.

3.3 Uma ubambo lwesibili luxega, isilinganiso sesifutho sikawoyela ku-AFC singancishiswa.

3.4 Ibhande eliphukile elinemfucumfucu yokuguqa uwoyela isikhathi eside kufanele lifuthwe ngamafutha wonke avuleke ukuze kugwenywe ukushintsha kohlobo lwamarola.

3.5 Ukulungisa lapho ushwabana, usongwa, ungqimba lwezintambo, i-loose roll