1. Babban da ƙananan goyon baya Rolls, aikin yi liners da tara mating surface gyara tsari.

Mataki na farko: sarrafa ramin waya na sama da ramin allura

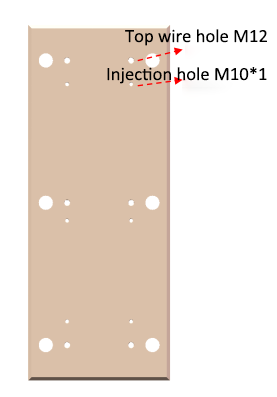

A cikin sabon farantin layi mai sarrafa manyan ramukan waya da ramukan allura, ƙayyadaddun ramukan saman waya shine M12, ƙayyadaddun ramukan allurar shine M10 X 1, adadin 6-12, amma kuma gwargwadon adadin bolts ɗin da aka shigar. da farantin layin da aka ɗaure, tsaka-tsaki da nisa tsakanin manyan ramukan waya guda biyu don kiyayewa a 300mm daidai, tsaka-tsaki da tsaka-tsaki tsakanin ramukan allura don kiyayewa tsakanin 200mm daidai, kewayon rarraba Kamar yadda aka nuna a cikin adadi.(Mai lura: ana iya sarrafa manyan ramukan waya da ramukan alluran kayan aiki a gaba yayin aikin sarrafa farantin layi)

Mataki na 2: Maganin saman

(1) man baking surface: yin amfani da oxygen acetylene don gyara farfajiyar rakiyar ya zama mai, danshi gasa mai tsabta.

(2) Maganin niƙa na ƙasa ko yashi.

(3) share fage.

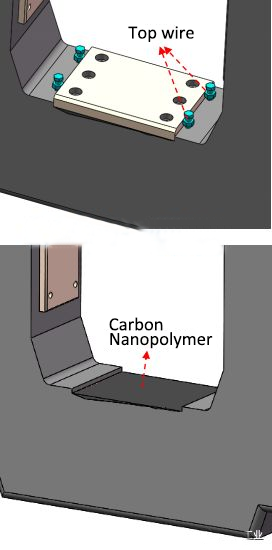

Mataki na 3: Goge wakili na saki kuma shigar da saman waya

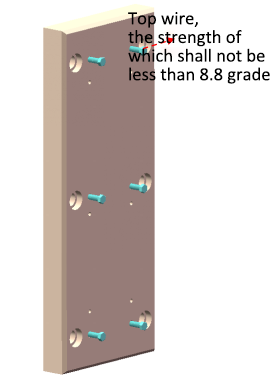

An fara tsabtace saman layin layi, ƙwanƙolin ƙulli da saman zaren waya na farko tare da ethanol mai anhydrous (haɗuwa 99.7%) kuma an bushe.Sa'an nan Layer na SD7000 saki wakili an goge a saman da kuma barin ya bushe.Manufar wannan shine don hana layin layi da saman waya daga haɗuwa da kayan Sorey carbon nanopolymer da sauƙaƙe cirewa da maye gurbin layin.A ƙarshe, an shigar da saman waya a kan layi kamar yadda aka nuna a cikin adadi.

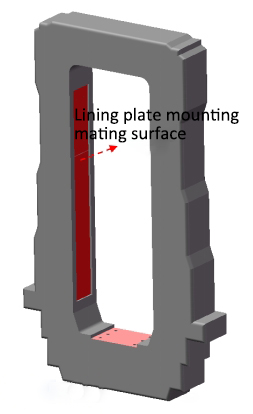

Mataki na 4: Matsayi kuma shigar da layin layi

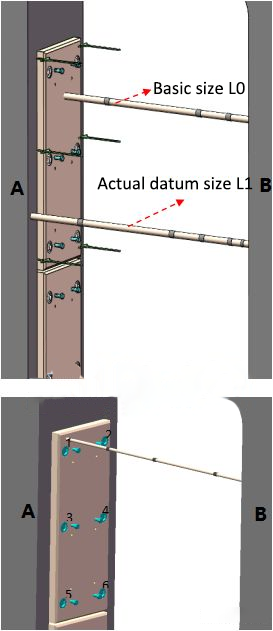

An ɗora layin layi zuwa firam ɗin kuma faranti na simmetrical guda biyu akan firam A da B suna samun matsayi guda ɗaya.Wannan tsari yana buƙatar ma'auni daidai tare da kayan saitin nesa na Laser don tabbatar da daidaiton shigarwar layi.

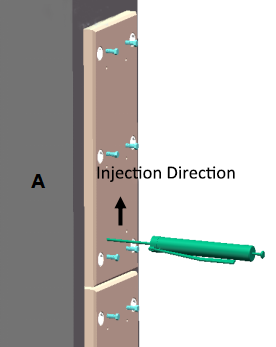

Mataki na 5: Allurar carbon nanopolymer abu ta saman ramin waya

An fara rufe tazarar da ke tsakanin gefen layin layin da firam ɗin tare da kayan nanopolymer na carbon nanopolymer don hana zubewar abu yayin aikin allura, kuma ana tanada ramukan huɗa iska a wurare masu ma'ana.

Abun da aka haɗe yana allura a cikin rata tsakanin layin layi da firam ta kayan aikin allura har sai kayan ya zube daga cikin ramukan iska.

Mataki na 6: Gyara kayan, tabbatar da girman, kuma ƙara maƙallan gyaran layi

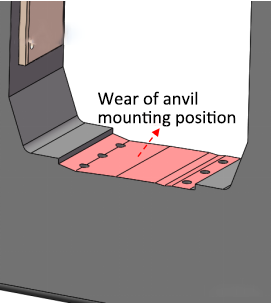

2. Anvil da frame mating surface lalacewa gyara tsari.

Mataki na farko: jiyya na saman

(1) man baking surface: yin amfani da iskar oxygen acetylene tara da za a gyara saman mai, danshi gasa mai tsabta.

(2) Maganin niƙa na ƙasa ko yashi.

(3) Tsaftace saman.

Mataki 2: Welding saman waya

Kamar yadda aka nuna a cikin adadi, weld na saman waya a gefen anvil, lambar kada ta kasance ƙasa da 4, kuma ƙayyadaddun waya mafi girma ya fi M12 girma.

Mataki na 3: Haɗa kuma shafa Solay carbon nanopolymer abu

(1) Yi ƙididdige ƙarar kayan da aka haɗe da ake buƙata bisa ga zurfin lalacewa da wurin lalacewa, sa'an nan kuma gauraya daidai gwargwado daidai gwargwado, haɗawa iri ɗaya ba tare da bambancin launi ba.

(2) Tsaftace saman ƙarfen maƙarƙashiya da ethanol mai anhydrous sannan a bushe.

(3) Shafa abin da ake saki a saman magudanar sai a bushe.

(4) Aiwatar da kayan da aka haɗa a ko'ina zuwa saman da za a gyara, yi amfani da shi daidai, girman girman girman ya fi girma fiye da girman girman lalacewa, kuma sanya kayan ya zama cikakke tare da saman karfe yayin aiwatar da aikace-aikacen.

Mataki na 4: Shigar kuma daidaita magudanar

Daidaita saman waya da ƙugiya masu ɗaure tururuwa, shigar da tururuwa, kuma isa ƙimar kewayon haƙurin matsayi da ake buƙata.

Mataki na 5: Maganin kayan aiki

Sama da 20℃, kiyaye kayan yana warkewa ta dabi'a na awanni 12 (ko dumama zuwa 60℃na tsawon sa'o'i 2), sannan a cire saman waya kuma a sake ƙara ƙulla gyaran maƙarƙashiya don kammala gyaran.

Lokacin aikawa: Janairu-30-2023