1. Amaroli asekelayo aphezulu naphansi, ama-roll liner omsebenzi kanye nenqubo yokulungisa indawo yokuhlangana kwama-rack.

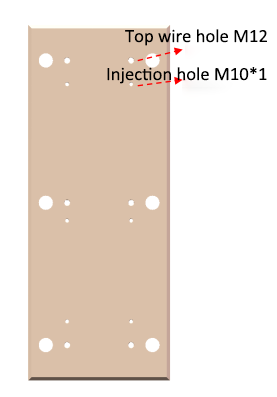

Isinyathelo sokuqala: ukucutshungulwa kwembobo yocingo ephezulu kanye nembobo yomjovo

Ku-liner plate entsha ecubungula izimbobo zezintambo eziphezulu nezimbobo zomjovo, ukucaciswa kwezimbobo zocingo eziphezulu yi-M12, ukucaciswa kwezimbobo zomjovo ngu-M10 X 1, inombolo engu-6-12, kodwa futhi ngokwenani lamabhawodi afakiwe. kanye nepuleti le-liner eliboshelwe, ibanga elivundlile nelime mpo phakathi kwezimbobo zezintambo ezimbili eziphezulu okufanele zigcinwe ku-300mm ezifanele, ibanga elivundlile nelime mpo phakathi kwezimbobo zomjovo ukuze kugcinwe ngaphakathi kuka-200mm okufanele, ububanzi bokusabalalisa Njengoba kuboniswe esithombeni.(Qaphela: izimbobo zezintambo eziphezulu kanye nezimbobo zokujova ezibonakalayo zingacutshungulwa kusenesikhathi phakathi nenqubo yokucubungula ipuleti liner)

Isinyathelo sesi-2: Ukwelashwa kwendawo

(1) uwoyela wokubhaka ongaphezulu: ukusetshenziswa kwe-oxygen acetylene ukulungisa indawo yokubeka ibe uwoyela, umswakama obhakwa uhlanzekile.

(2) ukugaya okungaphezulu noma ukwelashwa kwe-sandblasting.

(3) ukuhlanza indawo.

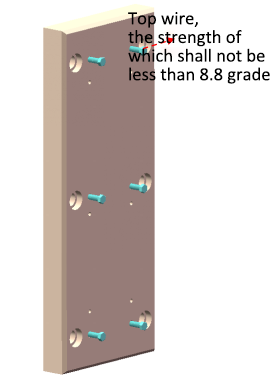

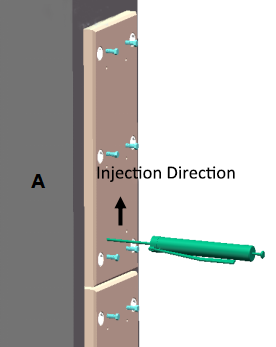

Isinyathelo sesi-3: Sula i-ejenti yokukhipha bese ufaka intambo ephezulu

Ingaphezulu le-liner, amabhawodi okubopha amalayini kanye nengaphezulu lentambo yocingo kuqala kuhlanzwa nge-ethanol engamanzi (concentration 99.7%) bese yomiswa.Bese ungqimba lwe-ejenti yokukhululwa ye-SD7000 lusulwa phezulu futhi luvunyelwe ukuba lome.Inhloso yalokhu ukuvimbela i-liner kanye nocingo olungaphezulu ekuboshweni yi-Sorey carbon nanopolymer material nokwenza kube lula ukususwa nokushintshwa kolayini.Ekugcineni, ucingo oluphezulu lufakwa kulayini njengoba kuboniswe emfanekisweni.

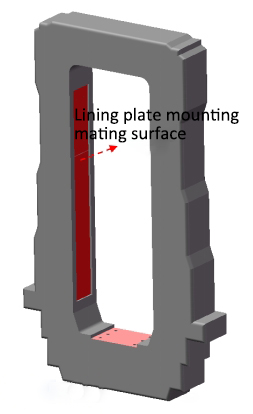

Isinyathelo sesi-4: Misa futhi ufake ilayini

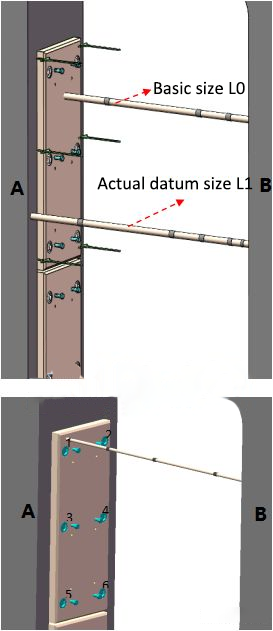

Ulayini ugxunyekwe kuhlaka futhi amapuleti amabili e-symmetrical liner kuhlaka A no-B abekwa kanyekanye.Le nqubo idinga ukulinganisa okunembile ngethuluzi lokusetha ibanga le-laser ukuze kuqinisekiswe ukunemba kokufakwa kolayini.

Isinyathelo sesi-5: Ukujovwa kwe-carbon nanopolymer ngembobo yocingo ephezulu

Igebe phakathi konqenqema lwelayini kanye nohlaka livalwa okokuqala ngqa nge-carbon nanopolymer material ukuvimbela ukuchitheka kwezinto ngesikhathi somjovo, futhi izimbobo zokungenisa umoya zigcinwe ezindaweni ezifanele.

Impahla ehlanganisiwe ijovwa esikhaleni esiphakathi kolayini nohlaka ngethuluzi lomjovo kuze kuchitheke okokusebenza emigodini yokukhipha umoya.

Isinyathelo sesi-6: Phakamisa impahla, qinisekisa usayizi, futhi uqinise amabhawodi okulungisa ulayini

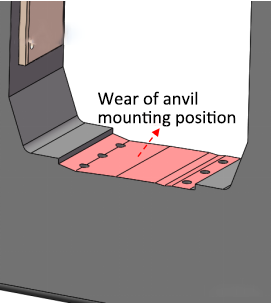

2. Inqubo yokulungisa izigqoko ze-anvil kanye nefreyimu yokuhlangana.

Isinyathelo sokuqala: ukwelashwa okungaphezulu

(1) uwoyela wokubhaka ongaphezulu: ukusetshenziswa kwe-oxygen acetylene rack ukuze kulungiswe uwoyela ongaphezulu, umswakama obhakwa uhlanzekile.

(2) ukugaya okungaphezulu noma ukwelashwa kwe-sandblasting.

(3) Ukuhlanza ubuso.

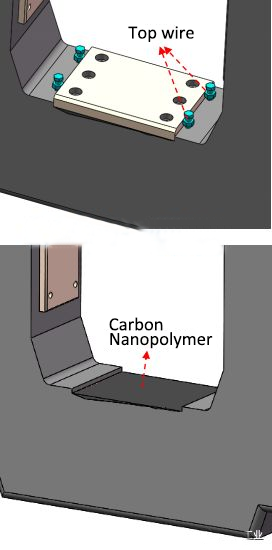

Isinyathelo sesi-2: I-Welding top wire

Njengoba kuboniswe emfanekisweni, shisela ucingo oluphezulu onqenqemeni lwe-anvil, inombolo akufanele ibe ngaphansi kuka-4, futhi ukucaciswa kocingo oluphezulu kukhulu kune-M12.

Isinyathelo sesi-3: Hlanganisa futhi usebenzise i-Solay carbon nanopolymer material

(1) Bala umthamo wezinto ezihlanganisiwe ezidingekayo ngokuya ngokujula kokugqoka nendawo egugile, bese uhlanganisa ngokuqinile ngokuya ngesilinganiso, uhlanganise ngokulinganayo ngaphandle kokuhluka kombala.

(2) Hlanza indawo engaphezulu ye-anvil iron nge-ethanol engenamanzi bese uyomisa.

(3) Sula ungqimba lwe-ejenti yokukhulula ebusweni be-anvil bese uyomisa.

(4) Gcoba into ehlanganisiwe ngokulinganayo endaweni ukuze ilungiswe, sebenzisa ngokulinganayo, ubukhulu bokujiya bukhulu kunosayizi wokujula wokugqokwa, futhi wenze impahla ihlanganiswe ngokugcwele nengaphezulu lensimbi phakathi nenqubo yokufaka isicelo.

Isinyathelo sesi-4: Faka futhi ulungise i-anvil

Lungisa intambo ephezulu kanye namabhawodi okubopha i-anvil, faka i-anvil, futhi ufinyelele inani elidingekayo lebanga lokubekezelela indawo.

Isinyathelo sesi-5: Ukwelapha okubalulekile

Ngaphezu kwama-20℃, gcina okokusebenza kokwelapha ngokwemvelo amahora angu-12 (noma ukushisisa kuya ku-60℃amahora angu-2), bese ususa ucingo olungaphezulu bese uqinisa ibhawudi lokulungisa i-anvil futhi ukuze uqedele ukulungisa.

Isikhathi sokuthumela: Jan-30-2023