Menene Ci gaba da Casting

Ci gaba da yin simintin gyare-gyare shine tsaka-tsakin hanyar haɗin gwiwa tsakanin yin ƙarfe da mirgina, wani ɓangaren da ba makawa a cikin aikin ƙarfe, da kuma muhimmin sashi na injin ƙarfe.

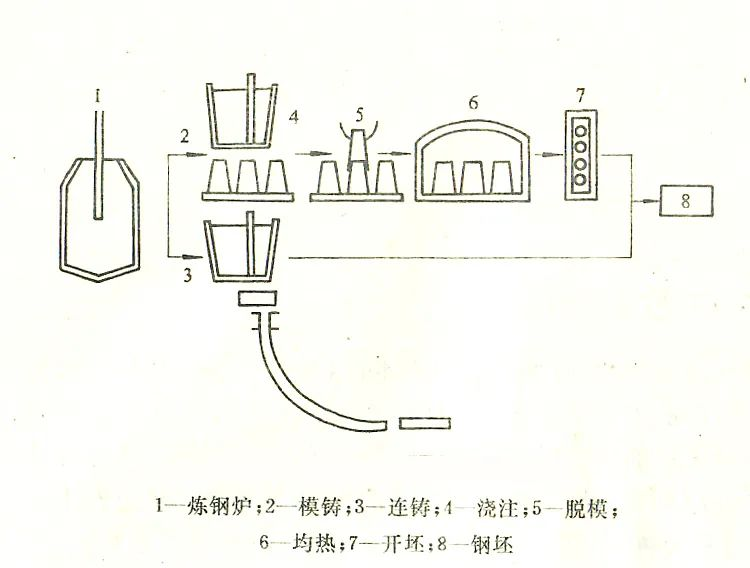

A cikin aiwatar da samar da nau'ikan samfuran ƙarfe daban-daban a cikin injinan ƙarfe, akwai hanyoyi guda biyu na yin amfani da ƙarfi da ƙarfe na ƙarfe: hanyar yin simintin mutuwa ta gargajiya da kuma hanyar ci gaba da yin simintin.

Mutuwar wasan kwaikwayo:karfen tanderun da aka zuba a lokaci-lokaci a cikin ingots da yawa, don ƙarfafa su zuwa siffa bayan sanyaya fitar da mold don samun simintin simintin.Saboda gyare-gyaren gyare-gyaren kowane zuba don yin mold, sanyaya sannan kuma rushewa, ya rufe yanki mai girma, ingantacciyar ingantaccen samarwa ba ta da yawa.

An samar da simintin gyare-gyare na dogon lokaci, adadin samarwa yana raguwa kowace shekara.Amma a halin yanzu, ci gaba da yin simintin gyare-gyare ba za a iya maye gurbinsa gaba ɗaya ba, alal misali, manyan simintin gyare-gyare da ƙirƙira na sassan makamashin nukiliya, injin injin injin injin ruwa, tan 10,000 na igiyoyi na jirgin ruwa da sauran manyan kauri na musamman na ƙarfe na iya amfani da simintin mutu kawai.

Ci gaba da yin wasan kwaikwayo:Karfe na ci gaba da gudana a cikin ladle na tsaka-tsaki, kuma ana allurar shi a cikin crystallizer bayan haɗuwa da shunting ta tsaka-tsakin ladle don yin sanyi da ƙarfafawa, yana haifar da simintin simintin gyare-gyare mara iyaka, wanda za a iya amfani dashi kai tsaye don yin birgima bayan yankewa.

Fa'idodi da halaye na ci gaba da simintin gyare-gyare.

Sauƙaƙe da samar da tsari, kawar da tafiyar matakai na mold simintin gyaran kafa, mold kau, mold gyara, ingot homogenization da billet budewa, ceton 40% a kayayyakin more rayuwa zuba jari, 30% a bene sarari, 40% a aiki halin kaka da kuma 15% a refractory amfani.

Inganta yawan amfanin ƙasa na ƙarfe, yana rage yawan asarar billets ta hanyar yanke kai da wutsiya, wanda zai iya ƙara yawan ƙarfe da kusan kashi 9%.

Yana rage amfani da makamashi a cikin tsarin samarwa, yana kawar da amfani da wutar lantarki a cikin tanderun buɗewa, wanda zai iya rage yawan makamashi da 1/4 zuwa 1/2.

Inganta injina da matakin sarrafa kansa na tsarin samarwa.

Gabatarwar tsarin simintin gyare-gyare na ci gaba

Tsarin tafiyar da ci gaba da samar da simintin gyaran kafa shine kamar haka

Ladle → tsaka-tsakin ladle → crystallizer → sanyaya na biyu → miƙewa billet → yankan → abin nadi → motar canja wurin billet (mai tura karfe) → simintin billet

Hanyar haɗin kai.

Matsakaicin ladle (buffering, rarraba)

Crystallizer (ƙarfafa kafa)

Na biyu sanyaya ( sanyaya, jagora clamping)

Na'ura mai ja da daidaitawa (ciwon billet, daidaitawa)

Lokacin aikawa: Janairu-06-2023