Yini i-Continuous Casting

Ukusakaza okuqhubekayo isixhumanisi esimaphakathi phakathi kokwenziwa nokugingqika kwensimbi, ingxenye ebalulekile yenqubo ye-metallurgical, kanye nengxenye ebalulekile yesigayo sensimbi.

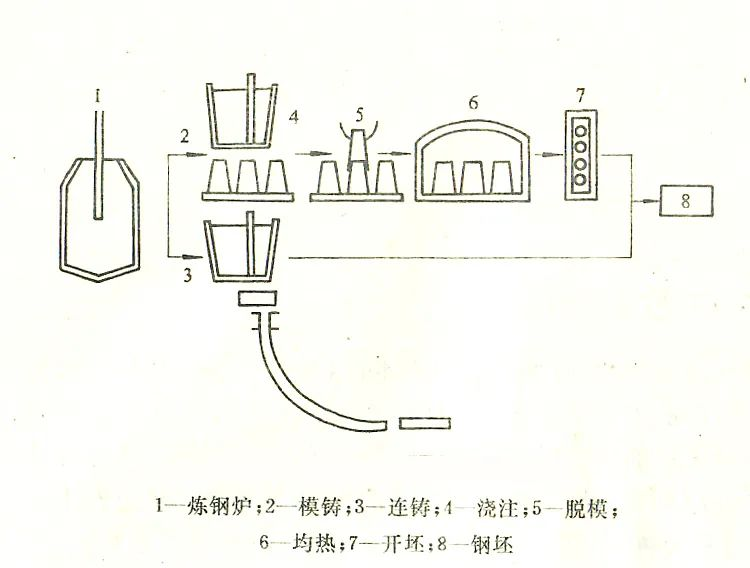

Enqubweni yokukhiqiza izinhlobo ezahlukene zemikhiqizo yensimbi ezigayweni zensimbi, kunezindlela ezimbili zokusebenzisa ukuqiniswa kwensimbi nokwenza: indlela yendabuko yokufaka ukufa kanye nendlela yokuphonsa eqhubekayo.

Ukulingisa ukufa:insimbi yesithando somlilo ethelwa ngezikhathi ezithile kuma-ingots amaningi, ukuze iqiniswe ibe yisimo ngemva kokupholisa isikhunta ukuze uthole i-cast billet.Ngoba ukubunjwa kwesikhunta ngakunye ukuthulula ukwenza isikhunta, ukupholisa bese kubunjwa, kuhlanganisa indawo enkulu, ukusebenza kahle kokukhiqiza okude kakhulu kuphansi.

I-Die casting iye yakhiqizwa isikhathi eside, isilinganiso sokukhiqiza siyancipha unyaka nonyaka.Kodwa okwamanje, ukusakaza okuqhubekayo akukwazi ukumiselela ngokuphelele ukujikijelwa kokufa, isibonelo, izingxenye ezinkulu zamandla enuzi nezakhiwe, ama-rotor ophephela aphehla amandla amanzi, amathani ayi-10,000 wezinsimbi zokuphotha umkhumbi nezinye izinsimbi ezikhethekile eziwugqinsi ezingasebenzisa i-die casting.

Ukusakaza okuqhubekayo:Insimbi igeleza ngokuqhubekayo ku-ladle emaphakathi, futhi ijova ku-crystallizer ngemva kokuxubana nokushunqiswa yi-ladle emaphakathi ukuze iphole futhi iqine, okuholela ku-billet ende engapheli, engasetshenziswa ngokuqondile ekukhiqizeni okugingqikayo ngemva kokusika.

Izinzuzo nezici zokulingisa okuqhubekayo.

Yenza lula inqubo yokukhiqiza, iqede izinqubo zokubunjwa kwesikhunta, ukususwa kwesikhunta, ukulungiswa kwesikhunta, i-ingot homogenization kanye nokuvulwa kwe-billet, ukonga u-40% ekutshalweni kwengqalasizinda, u-30% endaweni yaphansi, u-40% ezindlekweni zokusebenza kanye no-15% ekusetshenzisweni okuphikisayo.

Isivuno sensimbi esithuthukisiwe, sinciphisa kakhulu ukulahlekelwa kwamabhilidi ngokusika ikhanda nomsila, okungandisa isivuno sensimbi cishe ngo-9%.

Yehlisa ukusetshenziswa kwamandla ohlelweni lokukhiqiza, iqede ukusetshenziswa kwamandla omlilo esithandweni sokuvula i-billet, enganciphisa ukusetshenziswa kwamandla ngo-1/4 kuya ku-1/2.

Ithuthukisa izinga lemishini nele-automation yenqubo yokukhiqiza.

Isethulo senqubo yokulingisa eqhubekayo

Inqubo yokugeleza kokukhiqizwa kokulingisa okuqhubekayo imi kanje

I-Ladle → i-ladle ephakathi → i-crystallizer → ukupholisa okwesibili → ukuqondisa i-billet → ukusika → isidlulisi se-roller → imoto yokudlulisa i-billet (umsunduzi wensimbi) → ukusakaza kwe-billet

Isixhumanisi esiyinhloko.

Iledi elimaphakathi (ukugcina imali, ukusatshalaliswa)

I-Crystallizer (i-solidification forming)

Ukupholisa kwesibili (ukupholisa, ukugoqa okuqondisayo)

Umshini wokudonsa nowokuqondisa (ukudonsa i-billet, ukuqondisa)

Isikhathi sokuthumela: Jan-06-2023