Yintoni i-Continuous Casting

Ukuphosa ngokuqhubekayo yikhonkco eliphakathi phakathi kokwenziwa kwentsimbi kunye nokuqengqeleka, inxalenye eyimfuneko yenkqubo ye-metallurgical, kunye nenxalenye ebalulekileyo yentsimbi yensimbi.

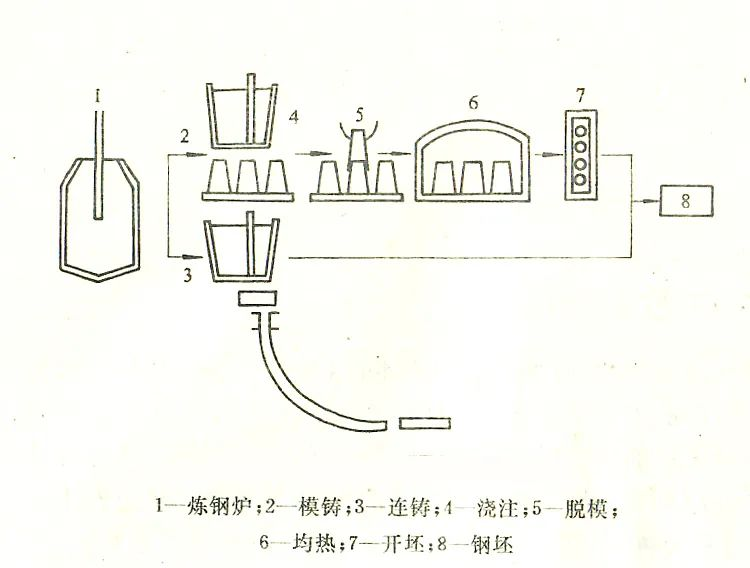

Kwinkqubo yokuvelisa iintlobo ezahlukeneyo zeemveliso zetsimbi kwiintsimbi zetsimbi, kukho iindlela ezimbini zokusebenzisa ukuqina kwetsimbi kunye nokwenza: indlela yendabuko yokufa kunye nendlela eqhubekayo yokuphosa.

Ukuphosa ukufa:intsimbi yesithando somlilo egalelwa ngamaxesha athile kwii-ingots ezininzi, ukuze iqiniswe ibe yimilo emva kokupholisa umngundo ukuze ufumane i-billet.Ngenxa yokuba ukugalela ukungunda ngakunye ukugalela ukwenza ukubumba, ukupholisa kwaye emva koko ukubunjwa, kugubungela indawo enkulu, imveliso ende yemveliso iphantsi.

I-Die casting iye yaveliswa ixesha elide, umlinganiselo wemveliso uyancipha unyaka nonyaka.Kodwa okwangoku, ukuphosa okuqhubekayo akunako ngokupheleleyo endaweni yokuphosa ukufa, umzekelo, i-cast cast enkulu kunye neendawo ezibunjiweyo zeeyunithi zamandla enyukliya, ii-rotors ze-injini ye-hydropower, iitoni ezili-10,000 ze-spindles zenqanawa kunye nezinye ubukhulu obukhulu bentsimbi ekhethekileyo inokusebenzisa kuphela ukuphosa ukufa.

Usasazo oluqhubekayo:Insimbi ihamba ngokuqhubekayo kwi-ladle ephakathi, kwaye ijojowe kwi-crystallizer emva kokuxuba kunye ne-shunting yi-ladle ephakathi ukupholisa kunye nokuqina, okubangelwa i-billet ye-cast engapheliyo, engasetyenziselwa ngokuthe ngqo kwimveliso yokuvelisa emva kokusika.

Izinto eziluncedo kunye neempawu zokuphosa okuqhubekayo.

Yenza lula inkqubo yokuvelisa, ukuphelisa iinkqubo zokubunjwa kwesikhunta, ukususwa kwesikhunta, ukulungiswa kwesikhunta, i-ingot homogenization kunye nokuvulwa kwe-billet, ukonga i-40% kwi-investment investment, i-30% kwindawo yomgangatho, i-40% kwiindleko zokusebenza kunye ne-15% ekusebenziseni i-refractory.

Ukuphuculwa kwemveliso yesinyithi, ukunciphisa kakhulu ukulahlekelwa kweebhilidi ngokusika intloko kunye nomsila, onokunyusa imveliso yesinyithi malunga ne-9%.

Ukunciphisa ukusetyenziswa kwamandla kwinkqubo yokuvelisa, ukuphelisa ukusetyenziswa kwamandla okutsha kwi-billet yokuvula isithando somlilo, enokunciphisa ukusetyenziswa kwamandla nge-1/4 ukuya kwi-1/2.

Ukuphucula inqanaba lomatshini kunye ne-automation yenkqubo yemveliso.

Intshayelelo yenkqubo eqhubekayo

Inkqubo yokuhamba kwemveliso eqhubekayo yokuphosa imi ngolu hlobo lulandelayo

Ileyile → ileli ephakathi → icrystallizer → ukupholisa okwesibini → ukolula ibhilethi → ukusika → isidluliseli sebhilethi → imoto yokuhambisa ibhilethi (isityhali sentsimbi) → ukuphoswa kwebillet

Ikhonkco elingundoqo.

Ileyile ephakathi (ubuffering, ukuhanjiswa)

ICrystallizer (ukwenza ukuqina)

Ukupholisa okwesibini (ukupholisa, ukugoba okukhokelayo)

Umatshini wokutsala kunye nokolula (ukutsalwa kwebillet, ukolula)

Ixesha lokuposa: Jan-06-2023