Dab tsi yog Nruam Casting

Nruam casting yog qhov sib txuas nruab nrab ntawm cov hlau ua thiab dov, ib feem tseem ceeb ntawm cov txheej txheem metallurgical, thiab ib feem tseem ceeb ntawm cov hlau zeb.

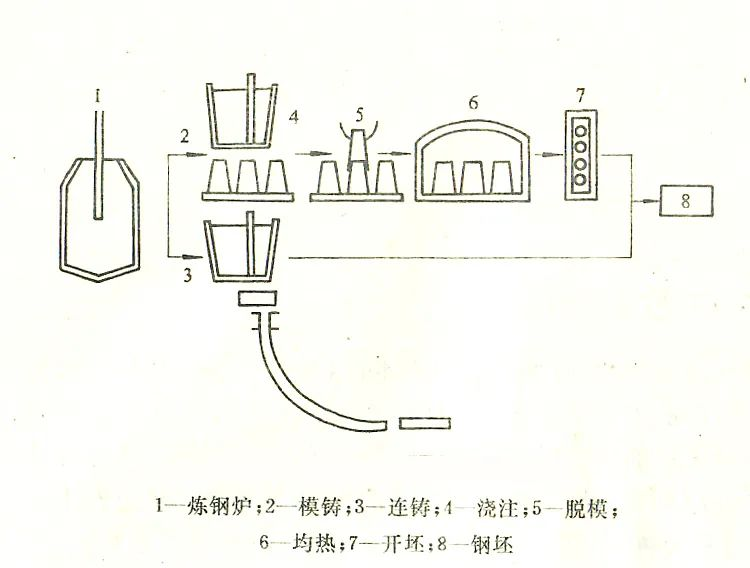

Nyob rau hauv tus txheej txheem ntawm kev tsim ntau yam steel khoom nyob rau hauv steel mills, muaj ob txoj kev ntawm kev siv steel solidification thiab sib sau: cov tsoos tuag casting txoj kev thiab txoj kev nruam casting.

Tuag casting:lub cub tawg steel sib sib zog nqus nchuav rau hauv ntau lub ingots, kom ruaj khov rau hauv cov duab tom qab txias tawm pwm kom tau cam khwb cia hlau.Vim hais tias pwm casting txhua pouring ua pwm, txias thiab ces demold, npog thaj tsam ntawm loj, kuj ntev lawm efficiency yog tsawg.

Tuag casting tau tsim los ntev, qhov sib piv ntau lawm yog ib xyoos ib zaug.Tab sis tam sim no, nruam casting tsis tuaj yeem hloov tag nrho tuag casting, piv txwv li, loj cam khwb cia thiab forged qhov chaw ntawm nuclear fais fab units, turbine rotors rau hydropower, 10,000 tons ntawm nkoj spindles thiab lwm yam loj thickness tshwj xeeb steel tsuas yog siv tuag casting.

Nruam casting:Cov hlau ntws tsis tu ncua mus rau hauv nruab nrab ladle, thiab yog txhaj rau hauv lub crystallizer tom qab sib tov thiab shunting los ntawm nruab nrab ladle kom txias thiab solidify, ua rau ib tug infinitely cam khwb cia billet ntev, uas yuav ncaj qha siv rau dov ntau lawm tom qab txiav.

Qhov zoo thiab cov yam ntxwv ntawm kev nruam casting.

Simplifies cov txheej txheem ntau lawm, tshem tawm cov txheej txheem ntawm pwm casting, pwm tshem tawm, pwm rectification, ingot homogenization thiab billet qhib, txuag 40% nyob rau hauv infrastructure peev, 30% nyob rau hauv pem teb chaw, 40% nyob rau hauv cov nqi khiav hauj lwm thiab 15% nyob rau hauv refractory noj.

Txhim kho hlau yield, txo qhov poob ntawm billets los ntawm kev txiav lub taub hau thiab tus Tsov tus tw, uas yuav ua rau kom cov hlau tawm los ntawm li 9%.

Txo kev siv hluav taws xob hauv cov txheej txheem tsim khoom, tshem tawm cov kev siv hluav taws xob sib xyaw hauv cov hluav taws xob qhib qhov cub, uas tuaj yeem txo qis kev siv hluav taws xob los ntawm 1/4 txog 1/2.

Txhim kho cov tshuab thiab automation qib ntawm cov txheej txheem ntau lawm.

Nruam casting txheej txheem qhia

Cov txheej txheem khiav ntawm nruam casting ntau lawm yog raws li nram no

Ladle → intermediate ladle → crystallizer → Secondary txias → billet straightening → txiav → roller conveyor → billet hloov tsheb (steel pusher) → billet casting

Core link.

Intermediate ladle (buffering, faib)

Crystallizer (solidification txoj kev)

Thib ob cooling (txias, coj clamping)

Rub thiab straightening tshuab (billet rub, straightening)

Post lub sij hawm: Jan-06-2023