Chii chinonzi Continuous Casting

Kuramba kuchikanda ndicho chinongedzo chepakati pakati pekugadzira simbi nekukunguruka, chikamu chakakosha chesimbi yesimbi, uye chikamu chakakosha chechigayo chesimbi.

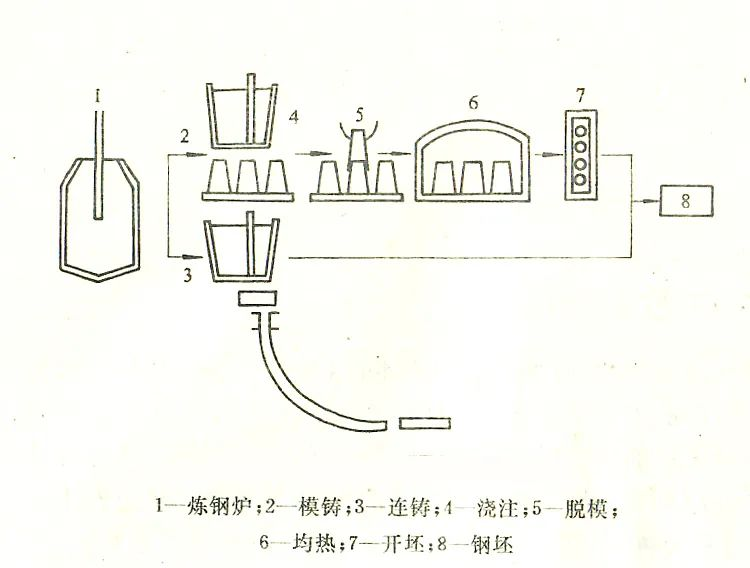

Mukugadzirwa kwemhando dzakasiyana dzezvigadzirwa zvesimbi mumagayo esimbi, kune nzira mbiri dzekushandisa simbi kusimba uye kugadzira: iyo yechinyakare kufa yekukanda nzira uye inoenderera yekukanda nzira.

Die casting:simbi yevira inodururwa mukati meingoti dzakawanda, kuti isimbiswe kuita chimiro mushure mekutonhodza kubva paforoma kuti iwane kukandwa billet.Nekuti mold inodira yega yega kuita mold, kutonhora uyezve dhizaini, inovhara nzvimbo yakakura, yakarebesa kugadzirwa kwakadzikira.

Die casting yakagadzirwa kwenguva yakareba, chiyero chekugadzira chiri kuderera gore negore.Asi pari zvino, kuramba kuchikanda hakugoni kutsiva zvachose kufa kukanda, semuenzaniso, hombe yakakandwa uye yakaumbwa zvikamu zvemagetsi enyukireya, turbine rotors ye hydropower, 10,000 matani ezvikepe zvinorukwa uye mamwe mahombe akakora akakosha simbi anogona chete kushandisa kufa kukanda.

Kuenderera mberi nekukandira:Simbi inoramba ichiyerera ichipinda mune yepakati ladle, uye inoiswa jekiseni mukristaro mushure mekusanganiswa uye shunting neiyo yepakati ladle kuti itonhore uye igosimba, zvichikonzera risingaperi refu rakakanda billet, rinogona kushandiswa zvakananga kukungurutsa kugadzirwa mushure mekucheka.

Zvakanakira uye maitiro ekuramba achikanda.

Inorerutsa maitiro ekugadzira, kubvisa maitiro ekukanda mold, kubvisa mold, kugadzirisa mold, ingot homogenization uye billet kuvhurwa, kuchengetedza 40% mukudyara kwezvivakwa, 30% munzvimbo yepasi, 40% mumitengo yekushandisa uye 15% mukushandisa kusinganzwisisike.

Kuvandudzwa kwegoho resimbi, zvakanyanya kuderedza kurasikirwa kwemabhiriti nekucheka musoro nemuswe, izvo zvinogona kuwedzera simbi yesimbi inenge 9%.

Inoderedza kushandiswa kwesimba mukugadzira, kubvisa kushandiswa kwesimba rekupisa mubillet yekuvhura vira, iyo inogona kuderedza kushandiswa kwesimba ne1/4 kusvika 1/2.

Inovandudza iyo mechanization uye otomatiki nhanho yemaitiro ekugadzira.

Kuenderera mberi kukandira maitiro ekusuma

Iyo nzira yekuyerera yekuenderera mberi kwekukanda kugadzirwa kunotevera

Ladle → ladle yepakati → crystallizer → kutonhora kwechipiri → billet kutwasanudza → kucheka → roller conveyor → billet kutamisa mota (simbi pusher) → billet casting

Core link.

Yepakati ladle (buffering, kugovera)

Crystallizer (solidification kugadzira)

Kutonhora kwechipiri (kutonhora, kutungamira clamping)

Kudhonza uye kutwasanudza muchina (billet kudhonza, kutwasanudza)

Nguva yekutumira: Jan-06-2023