1, Purity thiab zoo ntawm kev sib raug zoo

Purity yog hais txog tus naj npawb, daim ntawv thiab kev faib tawm ntawm cov khoom tsis yog hlau hauv cov hlau.Piv nrog tuag casting,nruam casting tshuabtxheej txheem kev sib txuas, nchuav lub sij hawm ntev, yog li kev suav nrog ntau qhov chaw, muaj pes tsawg leeg kuj yog qhov nyuaj dua;inclusions los ntawm cov crystallizer kua theem kab noj hniav floating ntau nyuaj, tshwj xeeb tshaj yog cov kev kub ceev ceev ntawm me me billet inclusions nyuaj dua kom tshem tawm.Lub xub ntiag ntawm inclusions rhuav tshem qhov txuas ntxiv thiab ntom ntawm cov hlau matrix.Qhov loj tshaj 50μm loj inclusions feem ntau nrog cov kab nrib pleb, uas ua rau lub sij hawm tsawg tus qauv ntawm lub nruam casting billet ua tsis tau tejyam, phaj delamination, thiab kev puas tsuaj rau saum npoo ntawm txias dov steel, thiab lwm yam, cov hlau yog heev teeb meem.Qhov loj, cov duab thiab kev faib tawm ntawm kev suav nrog rau qhov zoo ntawm cov hlau kuj txawv, yog tias cov inclusions me me, kheej kheej, diffuse tis, qhov cuam tshuam rau qhov zoo ntawm cov hlau ntau dua li qhov concentration ntawm qhov muaj tsawg dua;thaum cov inclusions loj, yog qhov teeb meem kev faib tawm, txawm tias tus naj npawb ntawm me me tab sis kuj muaj teeb meem ntau dua rau cov khoom zoo.

Piv txwv li: los ntawm kev sib sib zog nqus-draw steel phaj xuas nrig ntaus cov khib nyiab tshawb xyuas pom tias cov kab nrib pleb muaj nyob ntawm 100 ~ 300μm tsis tu ncua CaO-Al2O3 thiab Al2O3 heterometallic loj suav nrog.

Piv txwv li, vim muaj Al2O3 inclusions nyob rau hauv daim tawv nqaij ntawm nruam casting billet, dov mus rau hauv lub nto ntawm lub tsheb daim ntawv nrog dub kab tsis xws luag, ua rau tsis zoo nto txheej ntawm daim ntawv.

Kuj tseem siv tau rau ntim tin-plated phaj, ntxiv rau cov kev xav tau ntawm kev ua haujlwm txias txias, qhov loj thiab tus naj npawb ntawm cov khoom suav nrog kuj muaj cov kev cai sib xws.Rau lub thickness ntawm 0.3 hli nyias steel phaj, nyob rau hauv 1m2 cheeb tsam, particle loj ntawm tsawg tshaj li 50μm inclusions yuav tsum tsawg tshaj li 5, thiaj li yuav ua tau tus nqi seem ntawm 0.05% los yog tsawg dua, uas yog, sib sib zog nqus xuas nrig ntaus 2000 DI cov kaus poom, flat tsawg dua 1 seem.Yog li pom tias nws tseem ceeb npaum li cas los txo tus naj npawb ntawm cov koom nrog hauvnruam casting billetslos txhim kho qhov zoo ntawm cov ntawv sib sib zog nqus kos hlau.

Rau cov hlau zoo heev (xws li 0.01 ~ 0.25mm txoj kab uas hla lub log steel hlau) thiab nyias steel phaj (xws li lub thickness ntawm 0.025mm tin-plated phaj), qhov loj ntawm cov inclusions muaj nyob rau hauv nws yog txawm ntau nruj yuav tsum tau.

Tsis tas li ntawd, qhov loj thiab tus naj npawb ntawm kev suav nrog rau qhov zoo ntawm cov hlau thiab qhov cuam tshuam ntawm thaj chaw tshwj xeeb ntawm cov cam khwb cia hlau.General slab thiab billet unit ntev ntawm thaj tsam (S) thiab ntim (V) piv rau 0.2 ~ 0.8.Nrog rau txoj kev loj hlob ntawm nyias phaj thiab nyias sawb tshuab, S / V mus txog 10 ~ 50, yog hais tias tib inclusions nyob rau hauv steel, nyias phaj thiab nyias sawb hlau, nws txhais tau hais tias inclusions ze rau lub nto ntawm lub cam khwb cia billet, qhov ntau dua. cuam tshuam rau kev tsim cov phaj nyias zoo.Yog li txo cov kev suav nrog hauv cov hlau tseem ceeb dua.

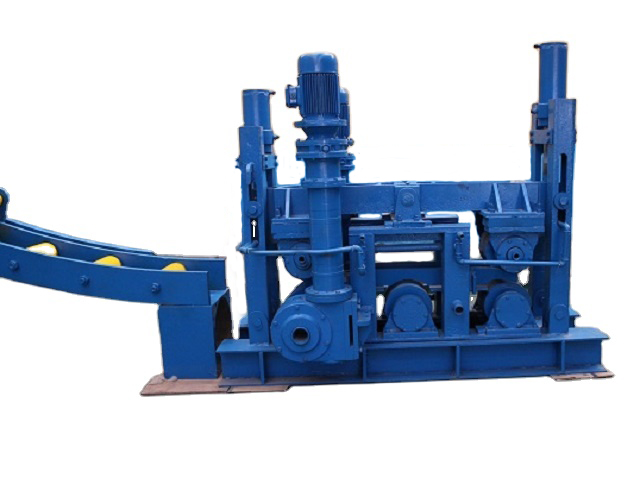

2, txhawm rau txhim kho qhov purity ntawm kev ntsuas

Txhim kho cov purity ntawm cov hlau yuav tsum nyob rau hauv cov hlau mus rau hauv lub crystallizer ua ntej, los ntawm cov txheej txheem kom txo tau cov pa phem ntawm cov hlau, thiab ua kom lub siab tshaj plaws inclusions ntawm cov hlau tsis suav nrog.Txhawm rau ua qhov no, cov kev ntsuas hauv qab no yuav tsum tau ua.

a, Tsis muaj slag tawm ntawm cov hlau: converter yuav tsum thaiv slag tawm ntawm cov hlau, hluav taws xob rauv siv eccentric rauv hauv qab ntawm cov hlau, los tiv thaiv cov slag rau hauv steel ladle lossis steel thoob, tank.

b, Raws li cov kev xav tau ntawm cov qib steel los xaiv qhov tsim nyog refining kho rau cov hlau ntshiab, txhim kho cov morphology ntawm inclusions.

C. Txais oxidation-free pouring technology.Tom qab kev kho kom zoo, cov ntsiab lus oxygen ntawm cov hlau molten tau raug txo kom tsawg dua 20 × 10-6;nyob rau hauv lub steel ladle → intermediate tank → crystallizer yog siv los tiv thaiv pouring;intermediate tank siv ob txheej ntawm slag npog tus neeg saib xyuas, cov hlau raug cais tawm ntawm huab cua kom tsis txhob oxidation theem nrab ntawm cov hlau molten.

d.Muab tag nrho ua si rau lub luag hauj lwm ntawm intermediate tank metallurgical purifier.Kev siv tshuab Ar nplawm, txhim kho cov dej ntws ntawm cov hlau, tshem tawm qhov chaw tuag ntawm lub tank nruab nrab;nce lub peev xwm ntawm lub tank nruab nrab thiab ua kom qhov tob ntawm lub pas dej ua ke, txuas ntxiv lub sijhawm nyob ntawm cov hlau molten nyob rau hauv lub tank nruab nrab, txhawb lub floating ntawm inclusions, thiab ntxiv purify cov hlau molten.

f, Nruam casting tshuab siv siab refractoriness, yaj poob yog me me, zoo refractory ntaub ntawv los txo cov inclusions nyob rau hauv cov hlau.

g, Muab kev ua si tag nrho rau lub luag haujlwm ntawm crystallizer molten steel purifier thiab billet nto zoo tswj.Qhov xaiv immersion spout yuav tsum muaj qhov tsim nyog qhib thiab lub kaum sab xis, tswj kev txav ntawm cov kwj deg, los txhawb kev sib cais ntawm kev suav nrog ntab;thiab ua tiav los ntawm kev ua tau zoo ntawm kev tiv thaiv slag, absorbing dissolved floating inclusions purified molten steel.Tsis tas li ntawd, cov crystallizer kuj tuaj yeem muab pub rau hauv cov hlau cored hlau kom ua tiav micro-alloying hauv crystallizer, uas tsis tsuas yog txhim kho qhov nqus ntawm cov hlau, thiab tuaj yeem tswj tau qhov muaj pes tsawg leeg ntawm cov hlau molten, kho cov qauv solidification, txhim kho cov morphology ntawm kev suav nrog, uas yog qhov tsim nyog rau kev txhim kho thiab ua kom huv ntawm cov hlau zoo.

h.Electromagnetic stirring technology yog siv los tswj kev txav ntawm cov dej txhaj tshuaj.Kev suav taw qhia tias nyob rau hauv lub xeev zoo li qub, ntau dua 1 hli slag hais ntab nrawm ntawm 100 ~ 200cm / s;thiab txhaj tshuaj ntws downward khiav ceev ntawm 60 ~ 10cm / s;pom crystallizer kua theem kab noj hniav nyob rau hauv qhov kev txhaj tshuaj flow strand cuam tshuam cheeb tsam inclusions floating yog nyuaj;Qee qhov kev suav nrog zoo li yuav raug kaw los ntawm kev sib zog ntawm cov dendrite.

Nyob rau hauv qhov tseeb, nyob rau hauv lub cam khwb cia billet nto hauv qab no 10 ~ 20cm feem ntau ntau dua inclusions.Lub installation ntawm electromagnetic brakes tuaj yeem cuam tshuam qhov kev txav ntawm kev txhaj tshuaj ntws, txhawb lub ntab ntawm kev suav thiab txhim kho cov purity ntawm cov hlau.

Post lub sij hawm: Dec-23-2022