1, Ubunyulu kunye nomgangatho wobudlelwane

Ubunyulu bubhekisela kwinani, ifom kunye nokuhanjiswa kwezinto ezingezizo zetsimbi kwintsimbi.Xa kuthelekiswa nokuphosa ukufa,umatshini wokuphosa oqhubekayoamakhonkco enkqubo, ixesha lokuthulula lide, ngoko ke ukubandakanywa koluhlu olubanzi lwemithombo, ukubunjwa kwakhona kunzima ngakumbi;ukubandakanywa ukusuka kwikristallizer yesigaba solwelo lomngxunya odadayo onzima ngakumbi, ngakumbi isantya esiphezulu somzobo we-billet encinci ebandakanya kunzima kakhulu ukungabandakanyi.Ubukho bokubandakanywa butshabalalisa ukuqhubeka kunye nobuninzi be-matrix yensimbi.Inkulu kune-50μm inclusions enkulu idla ngokukhatshwa kukuqhekeka, okukhokelela kumaxesha aphantsi isakhiwo se-billet eqhubekayo yokuphosa ayiphumelelanga, i-plate delamination, kunye nomonakalo kumphezulu wentsimbi epholileyo, njl., intsimbi iyingozi kakhulu.Ubungakanani, imilo kunye nokusabalalisa okufakiwe kumgangatho wensimbi kukwahluke, ukuba ukufakwa kuncinci, i-spherical, i-diffusable distribution, impembelelo kumgangatho wetsimbi kunokugxininiswa kobukho obuncinci;xa ukufakwa kukhulu, kukwabiwa kwengozi, nangona inani elincinci kodwa liyingozi ngakumbi kumgangatho wemveliso.

Umzekelo: ukusuka kwipleyiti etsalwe nzulu yokugqobhoza ukuhlolwa kwe-crack scrap yafumanisa ukuba iintanda zikhona kwi-100 ~ 300μm engaqhelekanga ye-CaO-Al2O3 kunye ne-Al2O3 ye-heterometallic inclusions enkulu.

Ngokomzekelo, ngenxa yobukho be-Al2O3 inclusions phantsi kwesikhumba se-billet eqhubekayo yokuphosa, ihlanganiswe ebusweni bephepha leemoto kunye neziphene zomgca omnyama, okubangelwa ukugquma komphezulu wephepha.

Kukho kwakhona kusetyenziselwa ukupakisha ipleyiti ye-tin-plated, ukongeza kwiimfuno zentsebenzo ephezulu ebanda kakhulu, ubungakanani kunye nenani lokufakwayo nazo zineemfuno ezihambelanayo.Ngobunzima be-0.3mm ipleyiti yentsimbi encinci, kwindawo ye-1m2, ubungakanani be-particle ubukhulu obungaphantsi kwe-50μm inclusions kufuneka bube ngaphantsi kwe-5, ukuze kuphunyezwe umlinganiselo we-scrap we-0.05% okanye ngaphantsi, oko kukuthi, ukubethelwa ngokujulile kwe-2000 DI cans, caba ngaphantsi kwe-1 scrap.Ke bona ukuba kubaluleke kangakanani ukunciphisa inani lokubandakanywa kwiiibhilethi eziqhubekayo zokuphosaukuphucula umgangatho wentsimbi yeshiti elizotywe nzulu.

Ngocingo lwentsimbi olucikizekileyo (olufana ne-0.01 ~ 0.25mm ububanzi bentsimbi yetayara) kunye nepleyiti yentsimbi encinci kakhulu (efana nobukhulu be-0.025mm yepleyiti ye-tin-plated), ubungakanani bokubandakanywa okuqulethwe kuyo yimfuneko engqongqo ngakumbi.

Ukongezelela, ubungakanani kunye nenani lokubandakanywa kumgangatho wensimbi kunye nefuthe lendawo ethile yendawo ye-billet cast.I-slab ngokubanzi kunye neyunithi ye-billet ubude bommandla wendawo (S) kunye nomthamo (V) umlinganiselo kwi-0.2 ~ 0.8.Ngophuhliso lwecwecwe elibhityileyo kunye netekhnoloji yomcu obhityileyo, S / V ukuya kuthi ga kwi-10 ~ 50, ukuba ukufakwa okufanayo kwintsimbi, ipleyiti encinci kunye nentsimbi ebhityileyo, oko kuthetha ukuba ukufakwa kufutshane nomphezulu webillet, okukhona impembelelo kwimveliso yomgangatho wepleyiti encinci.Ngoko ukunciphisa ukufakwa kwintsimbi kubaluleke kakhulu.

2, Ukuphucula ukucoceka kwamanyathelo

Ukuphucula ukucoceka kwentsimbi kufuneka kube kwintsimbi kwi-crystallizer ngaphambili, ukusuka kwinkqubo yokunciphisa ukungcola kwentsimbi, kwaye ukwandise ukubandakanywa kwintsimbi engabandakanywayo.Ukuza kuthi ga ngoku, la manyathelo alandelayo kufuneka athathwe.

a, Akukho slag ngaphandle kwentsimbi: umguquli kufuneka avimbe i-slag ngaphandle kwentsimbi, isithando somlilo sombane usebenzisa i-eccentric furnace ezantsi ngaphandle kwentsimbi, ukukhusela i-slag kwi-ladle yensimbi okanye ibhakethi yensimbi, itanki.

b, Ngokweemfuno zebakala lentsimbi ukukhetha unyango olufanelekileyo lokucoca kwintsimbi ecocekileyo, ukuphucula i-morphology of inclusions.

C. Yamkela iteknoloji yokugalela ngaphandle kwe-oxidation.Emva kokucoca unyango, umxholo we-oksijeni wensimbi etyhidiweyo uncitshiswe ngaphantsi kwe-20 × 10-6;kwi-ladle yensimbi → itanki ephakathi → i-crystallizer isetyenziselwa ukukhusela ukugalela;itanki ephakathi usebenzisa i-double layer of slag covering agent, intsimbi ibekwe yodwa emoyeni ukuze igweme i-oxidation yesibini yensimbi etyhidiweyo.

d.Nika umdlalo opheleleyo kwindima yesicoci se-metallurgical tank.Ukusetyenziswa kokuvuthela kwe-Ar ukuvuselela, ukuphucula ukuhamba kwentsimbi, ukuphelisa indawo efileyo yetanki ephakathi;ukwandisa umthamo wetanki eliphakathi kwaye wenze nzulu ubunzulu bechibi lokunyibilika, ukwandisa ixesha lokuhlala lentsimbi etyhidiweyo kwitanki ephakathi, ukukhuthaza ukudada kokubandakanywa, kunye nokuhlambulula ngakumbi intsimbi etyhidiweyo.

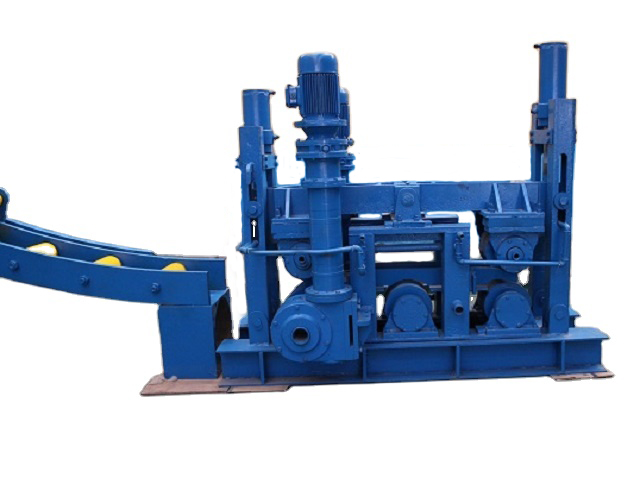

f, Inkqubo eqhubekayo yomatshini wokulahla isebenzisa i-refractoriness ephezulu, ilahleko yokunyibilika incinci, izinto ezichasayo eziphezulu zokunciphisa ukufakwa kwintsimbi.

g, Nika umdlalo opheleleyo kwindima yesicoci sentsimbi etyhidiweyo yecrystallizer kunye nesilawuli somgangatho webillet.I-spout yokucwiliswa ekhethiweyo kufuneka ibe nengqiqo yokuvula imilo kunye ne-angle, ukulawula ukuhamba kwe-injection stream, ukukhuthaza ukuhlukana kwe-inclusions floating;kwaye incediswe kukusebenza kakuhle kwe-slag yokukhusela, ukufunxa inclusions ezinyibilikayo ezidadayo ezihlambulukileyo zentsimbi etyhidiweyo.Ukongeza, i-crystallizer inokondliwa kwi-cored alloy wire ukufezekisa i-micro-alloying kwi-crystallizer, engaphuculi kuphela izinga lokufunxa kwe-alloy, kwaye inokulawula ngokuchanekileyo ukubunjwa kwentsimbi etyhidiweyo, ukulungelelanisa isakhiwo sokuqina, ukuphucula i-morphology of inclusions, efanelekileyo ekuphuculeni nasekuhlambululeni umgangatho wensimbi.

h.Itekhnoloji yokuvuselela i-Electromagnetic isetyenziselwa ukulawula ukuhamba komjelo wenaliti.Ubalo lubonisa ukuba kwimeko engatshintshiyo, amasuntswana e-slag angaphezu kwe-1mm adada kwisantya esimalunga ne-100 ~ 200cm / s;kunye nesantya sokuhamba sokuhla sokuhla se-60 ~ 10cm / s;ebonakalayo crystallizer ulwelo isigaba umngxuma ngaphakathi naliti flow flow strand indawo yempembelelo inclusions ezidadayo kunzima;ezinye izinto ezifakiweyo zinokuthi zibanjwe ngokuqiniswa kwe-dendrite.

Enyanisweni, kumphezulu we-billet owenziwe ngaphantsi kwe-10 ~ 20cm ngokuphindaphindiweyo ukubandakanywa okuphezulu.Ukufakwa kweziqhoboshi ze-electromagnetic kunokuthintela ukuhamba kwenaliti, ukukhuthaza ukudada okufakiweyo kunye nokuphucula ukucoceka kwentsimbi.

Ixesha lokuposa: Dec-23-2022