1, Bohloeki le boleng ba kamano

Bohloeki bo bolela palo, sebopeho le kabo ea li-inclusions tse se nang tšepe ka tšepe.Ha ho bapisoa le lefu la ho lahla,mochini o tsoelang pele oa ho lahlalihokelo tsa ts'ebetso, nako ea ho tšela e telele, ka hona, li-inclusions tsa mehloli e mengata e fapaneng, sebopeho se boetse se rarahane haholo;li-inclusions tse tsoang ho crystallizer liquid phase cavity e phallang ka thata ho feta, haholo-holo lebelo le phahameng la ho taka la li-inclusions tse nyenyane tsa billet tse thata ho feta ho li kenyelletsa.Ho ba teng ha li-inclusions ho senya ho tsoela pele le ho teteana ha matrix a tšepe.Kholo ho feta 50μm inclusions kholo hangata tsamaea le mapetsong a, ho fella ka linako tse tlaase sebopeho sa billet tsoela pele ho lahla o ile a hlōleha, poleiti delamination, 'me senya holim'a tšepe phuthoa a batang, joalo-joalo, tšepe e kotsi haholo.Boholo, sebōpeho le kabo ea li-inclusions ka boleng ba tšepe li boetse li fapane, haeba li-inclusions li le nyenyane, li le selikalikoe, li arola kabo, phello ea boleng ba tšepe ho feta ho tsepamisa mohopolo oa ho ba teng ho fokolang;ha li-inclusions li le khōlō, ke kabo ea tšohanyetso, le hoja palo ea tse nyenyane empa e boetse e le kotsi ho feta boleng ba sehlahisoa.

Ka mohlala: ho tloha botebong ba tšepe poleiti punching crack scrap hlahloba fumana hore mapetsong ba teng ka 100 ~ 300μm irregular CaO-Al2O3 le Al2O3 heterometallic khōlō inclusions.

Ka mohlala, ka lebaka la ho ba teng ha li-inclusions tsa Al2O3 tlas'a letlalo la billet e tsoelang pele ea ho lahla, e phuthetsoe ka holim'a letlapa la likoloi le nang le mefokolo e motšo, e leng se bakang ho roala holimo ho futsanehileng.

Ho boetse ho na le tse sebelisetsoang ho paka poleiti e entsoeng ka tin-plated, ntle le litlhoko tsa ts'ebetso e phahameng e batang ea ho etsa, boholo le palo ea li-inclusions le tsona li na le litlhoko tse lumellanang.Bakeng sa botenya ba poleiti ea tšepe e tšesaane ea 0.3mm, sebakeng sa 1m2, boholo ba likaroloana tse ka tlase ho 50μm li lokela ho ba ka tlase ho 5, e le ho fihlela sekhahla sa sekhechana sa 0.05% kapa ka tlase, ke hore, ho phunya ka likoti tse 2000 tsa DI, e bataletse ka tlase ho 1 sekhechana.Kahoo bona hore na ho bohlokoa hakae ho fokotsa palo ea li-inclusionsli-billet tse tsoelang peleho ntlafatsa boleng ba tšepe e huloang ka botebo.

Bakeng sa terata e ntle haholo ea tšepe (joalo ka terata ea tšepe ea thaere ea 0.01 ~ 0.25mm bophara) le poleiti ea tšepe e tšesaane haholo (joalo ka botenya ba 0.025mm tin-plated plate), boholo ba lintho tse kenyellelitsoeng ho eona ke litlhoko tse thata le ho feta.

Ho phaella moo, boholo le palo ea li-inclusions ka boleng ba tšepe le phello ea sebaka se itseng sa holim'a billet e entsoeng.Kakaretso ea slab le billet unit bolelele ba sebaka se ka holimo (S) le bophahamo ba modumo (V) ho 0.2 ~ 0.8.Ka nts'etsopele ea poleiti e tšesaane le thekenoloji e tšesaane, S / V ho fihlela ho 10 ~ 50, haeba li-inclusions tse tšoanang ka tšepe, poleiti e tšesaane le tšepe e tšesaane, ho bolela hore li-inclusions tse haufi le holim'a billet e kholoanyane. tšusumetso tlhahisong ea boleng ba poleiti e tšesaane.Kahoo ho fokotsa li-inclusions ka tšepe ho bohlokoa haholo.

2, Ho ntlafatsa bohloeki ba mehato

Ntlafatsa bohloeki ba tšepe e lokela ho ba ka har'a tšepe ka har'a crystallizer pele, ho tloha ts'ebetsong ho fokotsa tšilafalo ea tšepe, le ho eketsa li-inclusions ho tloha tšepe e sa kenyelletsoeng.Ho finyella sena, mehato e latelang e lokela ho nkoa.

a, Ha ho slag tsoa tšepe: converter lokela ho thibela slag tsoa tšepe, sebōpi sa motlakase sebelisa eccentric sebōpi botlaaseng tsoa tšepe, ho thibela slag ka ladle tšepe kapa tšepe nkhong, tanka.

b, Ho ea ka litlhoko tsa sehlopha sa tšepe ho khetha phekolo e nepahetseng ea ho hloekisa ho tšepe e hloekileng, ho ntlafatsa morphology ea inclusions.

C. Amohela thekenoloji ya ho tshela ntle le oxidation.Ka mor'a ho hloekisa phekolo, oksijene ea tšepe e entsoeng ka tšepe e qhibilihisitsoeng e fokotsehile ho feta 20 × 10-6;ka ladle ea tšepe → tanka e bohareng → crystallizer e sebelisoa ho sireletsa ho tšela;tanka e bohareng e sebelisa lera le habeli la sekoaelo sa slag, tšepe e arohane le moea ho qoba oxidation ea bobeli ea tšepe e qhibilihisitsoeng.

d.Fana ka papali e felletseng ea karolo ea tanka e bohareng ea metallurgical purifier.Tšebeliso ea ho bululela Ar e susumetsang, ho ntlafatsa phallo ea tšepe, ho felisa sebaka se shoeleng sa tanka e bohareng;eketsa bokhoni ba tanka e bohareng le ho tebisa botebo ba letamo la ho qhibiliha, ho eketsa nako ea ho lula ha tšepe e qhibilihisitsoeng ka tanka e bohareng, ho khothalletsa ho phalla ha li-inclusions, le ho tsoela pele ho hloekisa tšepe e qhibilihisitsoeng.

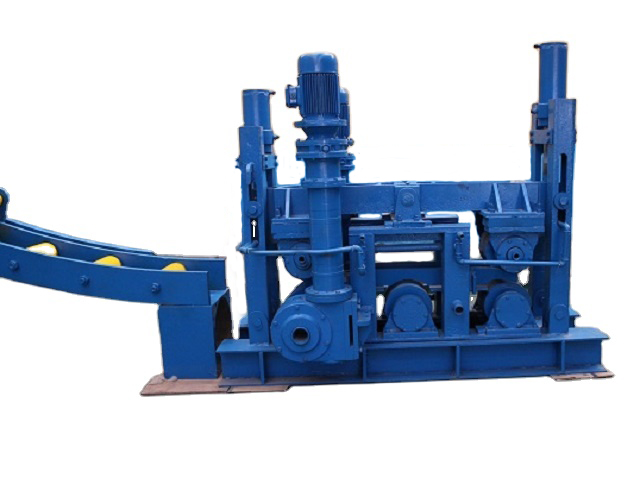

f, Sistimi e tsoelang pele ea mochini oa mochini e sebelisa refractoriness e phahameng, tahlehelo ea ho qhibiliha e nyane, lisebelisoa tsa boleng bo holimo tse refractory ho fokotsa li-inclusions tsa tšepe.

g, Fana ka papali e felletseng ea karolo ea sehloekisi sa tšepe e qhibilihisitsoeng sa crystallizer le selaoli sa boleng ba boleng ba billet.Sekoti sa ho qoelisoa se khethiloeng se lokela ho ba le sebopeho se utloahalang sa ho bula le sekhutlo, ho laola motsamao oa molapo oa ente, ho khothaletsa karohano ea li-inclusions tse phaphametseng;'me e tlatsitsoe ke ts'ebetso e ntle ea slag ea tšireletso, e monyang li-inclusions tse phaphametseng tse hloekisitsoeng tse entsoeng ka tšepe e qhibilihisitsoeng.Ntle le moo, kristale e ka feptjoa hape ka terata ea motsoako oa cored ho fihlela li-micro-alloying ka har'a kristale, e sa ntlafatse sekhahla sa ho monya ha motsoako, hape e ka laola ka nepo sebopeho sa tšepe e qhibilihisitsoeng, ea lokisa sebopeho sa ho tiisa, ntlafatsa morphology ea inclusions, e leng ho loketseng ho ntlafatsa le ho hloekisa boleng ba tšepe.

h.Theknoloji ea electromagnetic e susumetsang e sebelisoa ho laola motsamao oa molapo oa ente.Lipalo li bontša hore boemong bo tsitsitseng, ho feta 1mm slag particles floating ea hoo e ka bang 100 ~ 200cm / s;'me ente e phalla ho theoha lebelo la phallo ea 60 ~ 10cm / s;bonahalang crystallizer mokelikeli mohato cavity ka hare ho ente phallo phallo strand tšusumetso sebakeng inclusions phaphametseng ke ho le thata;li-inclusions tse ling li ka 'na tsa tšoaroa ke ho tiisa dendrite.

Ha e le hantle, ka ho lahla billet holim'a ka tlaase ho 10 ~ 20cm hangata phahameng inclusions.Ho kenngoa ha mariki a motlakase ho ka thibela ho tsamaea ha ente, ho khothalletsa ho phalla ha li-inclusions le ho ntlafatsa bohloeki ba tšepe.

Nako ea poso: Dec-23-2022