1, Ịdị ọcha na ịdị mma nke mmekọrịta

Ịdị ọcha na-ezo aka na ọnụ ọgụgụ, ụdị na nkesa nke ihe ndị na-abụghị ọla na ígwè.Tụnyere nkedo anwụ,igwe nkedo na-aga n'ihuusoro njikọ, wụsa oge na-adị ogologo, ya mere inclusions nke a dịgasị iche iche nke isi mmalite, mejupụtara dịkwa mgbagwoju anya;nsonye sitere na oghere mmiri mmiri crystallizer na-ese n'elu ihe siri ike karị, ọkachasị oke ịse ọsọ nke obere billet inclusions siri ike iwepụ.Ọnụnọ nke ntinye na-ebibi ihe na-aga n'ihu na njupụta nke matrix ígwè.Nnukwu ihe karịrị 50μm nnukwu inclusions na-esonyere ya na mgbawa, na-ebute obere oge nhazi nke billet na-aga n'ihu na-akụ afọ n'ala, delamination efere, na mmebi n'elu igwe oyi na-atụ, wdg, ígwè ahụ na-emerụ ahụ.The size, udi na nkesa nke inclusions na àgwà nke ígwè bụkwa dị iche iche, ma ọ bụrụ na inclusions bụ obere, spherical, diffous nkesa, mmetụta na àgwà nke ígwè karịa ịta nke ọnụnọ nke obere;mgbe inclusions bụ nnukwu, bụ mberede nkesa, ọ bụ ezie na ọnụ ọgụgụ nke obere ma ọzọ na-emerụ ka ngwaahịa mma.

Ọmụmaatụ: site miri-adọkpụ efere efere punching crack scrap nnyocha chọpụtara na cracks dị na 100 ~ 300μm oge mgbe CaO-Al2O3 na Al2O3 heterometallic nnukwu inclusions.

Dị ka ihe atụ, n'ihi na ọnụnọ nke Al2O3 inclusions n'okpuru akpụkpọ nke na-aga n'ihu nkedo billet, akpọrepu n'ime n'elu akpakanamde mpempe akwụkwọ na nwa ahịrị ntụpọ, butere ogbenye elu mkpuchi nke mpempe akwụkwọ.

A na-ejikwa ya maka ịkwakọba efere tin-plated, na mgbakwunye na ihe achọrọ nke ịrụ ọrụ oyi dị elu, nha na ọnụ ọgụgụ nke ntinye nwekwara ihe ndị chọrọ.N'ihi na ọkpụrụkpụ nke 0.3mm mkpa ígwè efere, na 1m2 ebe, urughuru size nke na-erughị 50μm inclusions kwesịrị ịbụ ihe na-erughị 5, iji nweta scrap ọnụego nke 0.05% ma ọ bụ obere, ya bụ, miri punching 2000 DI Mkpọ, flat na-erughị 1 iberibe.Ya mere, lee ka ọ dị mkpa ibelata ọnụ ọgụgụ ntinye nampempe akwụkwọ nkedo na-aga n'ihuiji melite ogo nke nchara mpempe akwụkwọ dị omimi.

Maka waya nchara mara mma (dị ka 0.01 ~ 0.25mm dayameta taya ígwè waya) na efere ígwè dị ezigbo mkpa (dị ka ọkpụrụkpụ nke 0.025mm tin-plated plate), nha nke inclusions dị na ya bụ ihe siri ike chọrọ.

Tụkwasị na nke ahụ, nha na ọnụ ọgụgụ nke ntinye aka na ịdị mma nke ígwè na mmetụta nke kpọmkwem n'elu elu nke billet nkedo.General slab na billet unit ogologo nke elu ebe (S) na olu (V) ruru na 0.2 ~ 0.8.Na mmepe nke mkpa efere na mkpa warara technology, S / V ruo 10 ~ 50, ma ọ bụrụ na otu inclusions na ígwè, mkpa efere na mkpa warara ígwè, ọ pụtara na inclusions nso n'elu nke nkedo billet, ka ukwuu mmetụta na mmepụta nke mkpa efere àgwà.Ya mere, belata ntinye na nchara dị mkpa karị.

2, Iji meziwanye ịdị ọcha nke usoro

Meziwanye ịdị ọcha nke nchara kwesịrị ịdị na nchara n'ime crystallizer tupu oge eruo, site na usoro iji belata mmetọ nke ígwè ahụ, ma mee ka ihe ndị a na-etinye na nchara na-ewepụ.Iji mezuo nke a, ekwesịrị ịme ihe ndị a.

a, Ọ dịghị slag si nchara: Ntụgharị kwesịrị igbochi slag si nchara, ọkụ ọkụ eletrik na-eji eccentric ọkụ ala si nchara, iji gbochie slag n'ime ígwè ladle ma ọ bụ ígwè ịwụ, tank.

b, Dị ka mkpa nke ọkwa nchara ịhọrọ ọgwụgwọ nchacha kwesịrị ekwesị na nchara dị ọcha, melite morphology nke inclusions.

C. Nweta teknụzụ ịwụsa na-enweghị oxidation.Mgbe emechara ọgwụgwọ, a na-ebelata ikuku oxygen nke ígwè a wụrụ awụ na-erughị 20 × 10-6;na ladle ígwè → etiti tank → crystallizer na-eji echebe wụsa;tankị etiti na-eji okpukpu abụọ nke ihe mkpuchi slag, ígwè dịpụrụ adịpụ na ikuku iji zere oxidation nke abụọ nke ígwè a wụrụ awụ.

d.Nye egwuregwu zuru oke n'ọrụ nke nchacha igwe nchara nke etiti.Ojiji nke ịfụ Ar na-akpali akpali, na-eme ka ọkpụkpụ ígwè dịkwuo mma, kpochapụ mpaghara nwụrụ anwụ nke tankị etiti;mee ka ikike nke tankị dị n'etiti dịkwuo elu ma mee ka omimi nke ọdọ mmiri gbazee, gbasaa oge obibi nke nchara a wụrụ awụ na tank nke etiti, na-akwalite ihe na-ese n'elu mmiri nke inclusions, na-eme ka ígwè ahụ gbazere dịkwuo ọcha.

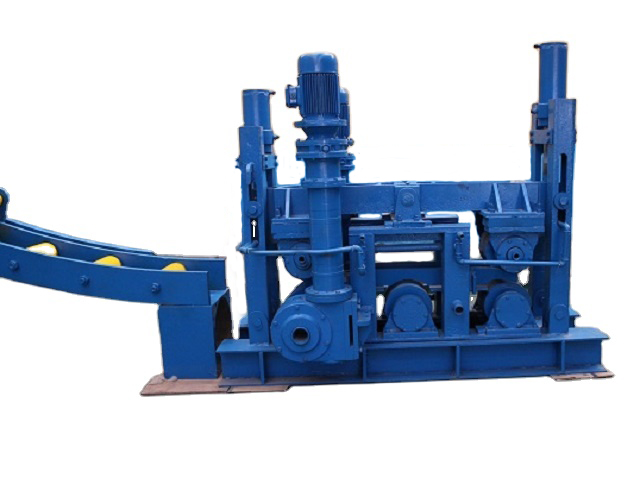

f, Igwe ihe nkedo na-aga n'ihu na-eji akwa refractoriness, mgbaze na-agbaze bụ obere ihe na-eme ka ọ dị elu iji belata ntinye na nchara.

g, Nye egwuregwu zuru oke maka ọrụ nke nchara kristal a wụrụ awụ na onye na-ahụ maka ịdịmma billet.Nhọrọ imikpu spout kwesịrị inwe ezi oghere udi na akụkụ, na-achịkwa ije nke injection iyi, iji kwalite nkewa nke inclusions sere n'elu;na complemented site ọma ịrụ ọrụ nke nchedo slag, absorbing etisasịwo sere n'elu inclusions ọcha gbazere nchara.Tụkwasị na nke ahụ, a pụkwara itinye crystallizer n'ime eriri alloy cored iji nweta micro-alloying na crystallizer, nke ọ bụghị nanị na-eme ka ọnụọgụ nke alloy dịkwuo mma, ma nwee ike ịchịkwa nhazi nke nchara a wụrụ awụ, gbanwee usoro nhazi siri ike, melite morphology nke inclusions, nke na-eme ka ọ dịkwuo mma na ime ka mma nke ígwè dị ọcha.

h.A na-eji teknụzụ mkpali eletrọnịkị chịkwaa mmegharị nke iyi ịgba ntụtụ.Mgbakọ na-egosi na na steeti static, ihe karịrị 1mm slag ahụ na-ese n'elu ọsọ nke ihe dịka 100 ~ 200cm / s;na injection na-agbada ọsọ ọsọ nke 60 ~ 10cm / s;a na-ahụ anya crystallizer mmiri mmiri na-adọ oghere n'ime injection eruba eruba strand mmetụta mpaghara inclusions sere n'elu siri ike;Ụfọdụ ntinye nwere ike ịdakwasị site na nkwụsi ike nke dendrite.

N'ezie, na nkedo billet elu n'okpuru 10 ~ 20cm na-adịkarị elu nsonye.Ntinye nke breeki electromagnetic nwere ike igbochi mmegharị nke ịgbanye ntụtụ, kwalite n'elu mmiri nke ntinye ma melite ịdị ọcha nke nchara.

Oge nzipu: Dec-23-2022