A, Aiki na yau da kullunmirgina niƙajihar

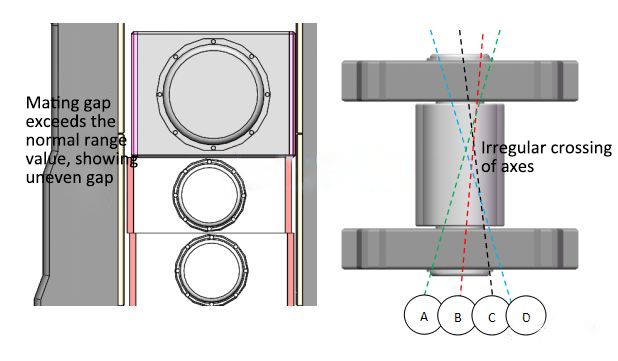

Girman taga sabon farantin niƙa sau da yawa yana cikin takamaiman kewayon haƙuri, gabaɗaya magana, juriyar girman taga galibi yana cikin kewayon +0.3 – +0.7mm, donyi niƙawurin zama don kafa tsayayye kuma daidaitaccen matsayi.

B, Farantin niƙa sa matsayi da haifar da bincike

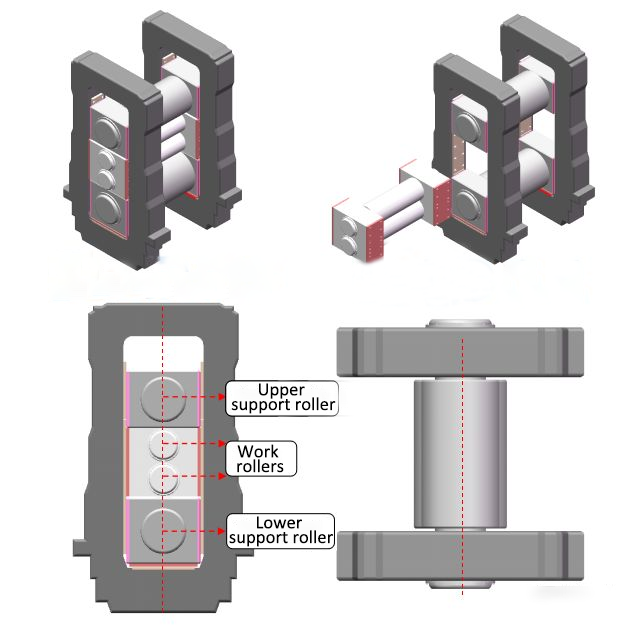

1. Saka matsayi

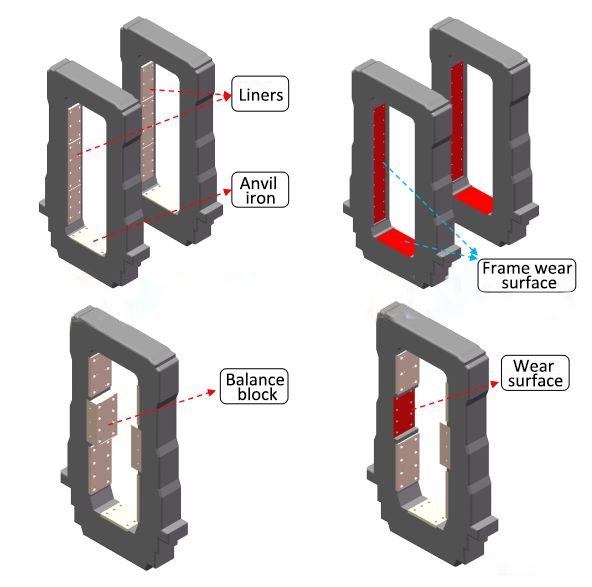

(1) Na sama da ƙananan goyon baya Rolls, aikin nadi liner da tara mating surface.

(2) Ƙarfin maƙarƙashiya da tarkacen magudanar ruwa.

(3) Ma'auni block (ko na'urar lanƙwasa) da kuma saman mating.

2. Nazarin abubuwan da ke haifar da lalacewa ta farantin

(1) Lalacewar ruwa mai sanyaya.

Kamar yadda mating surface tsakanin liner da bitar ne karfe-to-karfe fit, karfe a cikin aiki tsari ko da ya kai a fairly high surface gama da flatness, amma biyu sassa a fit ba zai iya isa 100% dace. , wanda zai haifar da rata tsakanin mating surface.A lokacin aikin samarwa, ruwa mai sanyaya zai shiga cikin farantin layi da ratar da ake yi na mating na niƙa, ruwan sanyi zai haifar da lalata a saman farantin niƙa, samar da wani Layer na oxide, don haka a cikin tsarin birgima, layin layi. farantin zai haifar da matsa lamba a kan sako-sako da oxide Layer pat, da dai sauransu, ta yadda rata za ta kara karuwa, wanda zai haifar da lalata da lalacewa na farantin kanta fiye da tsanani, har sai tasirin ingancin samfuran birgima.Lalacewar ruwa mai sanyaya ruwa a kan farantin niƙa, yana ɗaya daga cikin mahimman dalilai na lalata da lalacewa na mirgina.

(2) Rashin gajiyar ƙarfe.

Tsarin aikin bita na bitar niƙa ta hanyar tasirin ƙarfin ƙarfi a kowane fanni, layin da kanta da layin layi da saman mating na farantin bitar za su haifar da gajiyar ƙarfe na yau da kullun, wanda ke haifar da halayen ƙarfe da kansa.

(3) Taushin saman.

Rashin daidaituwar yanayin kai tsaye yana shafar yankin mating tsakanin layin da firam, saman saman bayan aikin injin milling shine kawai kusan 50%, kuma saman mating bayan kammala injin na iya kaiwa kusan 70%.Tare da ƙaramin yanki, mafi girman matsa lamba kowane yanki na yanki, guntuwar zagayowar gajiyar ƙarfe, gajeriyar rayuwar sabis.

(4) Nakasar Rack.

Wurin zama mai ɗaukar nauyi akan injin niƙa yana tsayawa ci gaba da tasiri tare da lalata saman layin, zai iya haifar da sauri zuwa ɓangaren tallafi na nakasawa.Saboda wannan ƙarin tazara, an ƙara ƙarin yancin motsi.Bayan da muka yi la'akari da tsayawar injin niƙa da yawa mun lura cewa haɓakar tazarar sharewa ba ta dace ba cikin tsayin tsayin daka, tare da mafi girman gibi yana faruwa a ƙasan layin mirgina.Hakanan akwai bambanci mai ban sha'awa tsakanin gefen tuƙi da gefen afareta.(b) Wannan motsi mai wuce gona da iri haɗe da canje-canje a matsayi ya haifar da sabani a tsaye maras so, wanda ya haifar da hayewar aikin nadi.

(5) Sake bolts ɗin da ke ɗaure layi yayin aikin niƙa.

Ana buƙatar bincika ƙusoshin masu ɗaure layin layi tare da ƙara matsawa akai-akai, kuma lokacin dubawa na yau da kullun ya kamata ya kasance lokacin da ake maye gurbin nadi.Saboda matsalolin sarrafa kayan aiki, ƙusoshin ba su da kyau kuma a kan lokaci, farantin layi da plaque na niƙa za su haifar da wani tazara a tsakanin su, ta yadda a lokacin aiki, farantin liner ya samar da wani ɗan fenti akan plaque kanta, wanda zai haifar da gajiyar karfe a saman plaque cikin kankanin lokaci, wanda hakan kan haifar da lalacewa da tsagewa.

(6) Muguwar da'ira.

Ƙarƙashin dindindin na tsayin daka na niƙa da aka kawo ta hanyar ci gaba da ɗaukar nauyin tasiri zai kara tsanantawa ta hanyar lalata kayan.Lokacin da layin ya fara motsawa, ƙullun gyaran gyare-gyare za su sassauta kuma su kasa riƙe layin da kyau a cikin firam.Wannan yana haifar da dama ga emulsions, tururi da gurɓatawa daga tsarin mirgina don shiga a bayan layin layi, don haka ƙara haɓakar lalata kayan aiki a baya na layin layi da kwafin kanta.

C, Tasirin lalacewan farantin niƙa da aka yi

1. Wucewa mai yawa.

A lokacin aikin mirgina, wurin zama mai ɗaukar hoto na tallafi, mirgine aikin da farantin layi a kan farantin a kan rata na mating yana ƙaruwa, yana samar da wani nau'in "slack" akan firam ɗin, yana ƙaruwa da gajiyawar firam, wanda ya haifar da m aiki na kayan aiki, vibration ne mai tsanani.

2. Support rollers, aikin rollers axis giciye.

Ci gaba da tasirin wurin zama a kan injin niƙa tare da haɓaka gajiyar gajiya a saman tsayawar na iya haifar da nakasu da sauri na sashin tallafi.Saboda wannan ƙarin tazara, an ƙara ƙarin yancin motsi.Bayan dubawa mun lura cewa yawancin gibin niƙa suna tsayawa tsayin daka ba su da daidaituwa cikin tsayin tsayin daka, tare da mafi girman gibin da ke faruwa a ƙasan layin mirgina.Hakanan an sami babban bambanci tsakanin gefen tuƙi da gefen mai aiki.Wannan matsananciyar motsin da aka haɗe tare da canje-canje a matsayi ya haifar da sabani a tsaye maras so, wanda ya haifar da hayewar aikin nadi.

3. Rashin ingancin takardar.

Samfurin da aka yi birgima ta wannan injin niƙa da ya wuce kima zai sami samfurin takarda tare da yanayin da ba a so lokacin da aka auna shi, kuma za a iya gano baka a cikin tsawon takardar, yana rage tsayin birgima.Zai shafi girman kauri da siffar faranti na tsiri, wanda zai shafi tasirin amfanin mai amfani na ƙasa.Canje-canje na kauri a cikin tsayi da girma a cikin giciye na iya faruwa.Siffar farantin za ta haifar da lahani, yana mai da siffar tsiri da bai dace da siffar farantin birgima ta al'ada ba.Canje-canje masu tsanani a cikin siffar farantin kuma na iya haifar da ƙirƙira niƙa, yana haifar da ƙarin raguwar lokacin niƙa da amfani.

Lokacin aikawa: Janairu-30-2023