A, Ukusebenza okuvamileumshini wokugayaisimo

Usayizi wefasitela wepuleti elisha lokugaya uvamise ukuba phakathi kwebanga elithile lokubekezelelana, ngokuvamile, ukubekezelela usayizi wewindi kuvame ukuba ku-+0.3 - +0.7mm, ku-umshini wokugayaisihlalo esiphethe ukuze kusungulwe isikhundla esizinzile nesinembile.

B, Indawo yokugqoka ipuleti lokugaya kanye nokuhlaziya imbangela

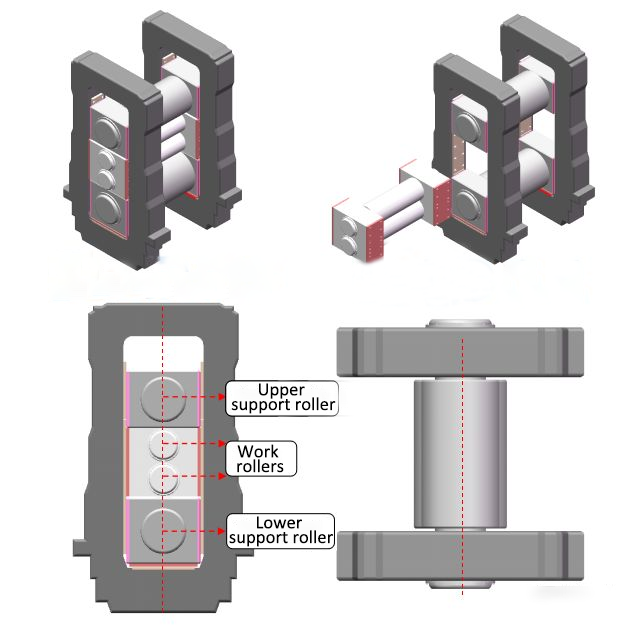

1. Gqoka isikhundla

(1) Amaroli asekelayo aphezulu naphansi, umugqa wokusebenza kanye nendawo yokukhwelana.

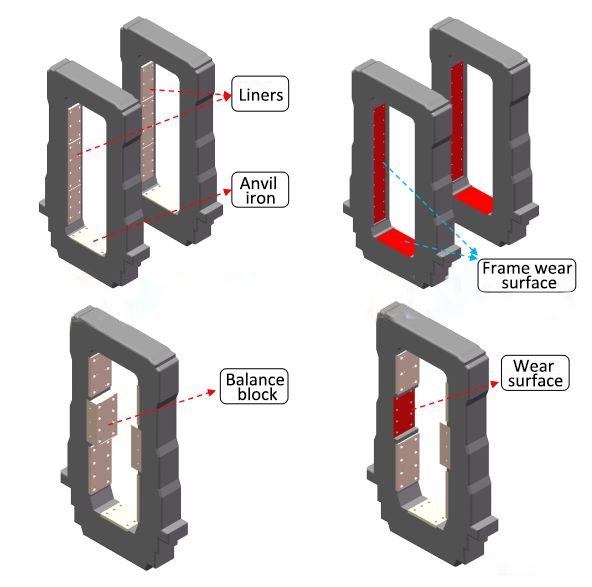

(2) Insimbi ye-anvil kanye ne-rack mating surface.

(3) I-balance block (noma i-roller egobayo) nendawo yokukhwelana yokubeka.

2. Ukuhlaziywa kwezimbangela zokuguga kwamapuleti okugaya

(1) Ukugqwala kwamanzi okupholisa.

Njengoba indawo yokukhwelana phakathi kwe-liner ne-workshop ilingana nensimbi-kuya-metal, insimbi enqubweni yokucubungula ngisho noma ifinyelela esiphethweni esiphezulu nesicaba, kodwa izingxenye ezimbili ezifanele azikwazi ukufinyelela ukulingana okungu-100%. , okuzodala igebe phakathi kwendawo yokukhwelana.Phakathi nenqubo yokukhiqiza, amanzi okupholisa azongena epuleti le-liner kanye negebe lendawo yokukhwelana yesigayo, amanzi okupholisa abangele ukugqwala ebusweni bepuleti lokugaya, enze ungqimba lwe-oxide, ukuze inqubo yokugoqa, i-liner ipuleti kuzobangela ingcindezi eqinile phezu okuxekethile oxide ungqimba pat, njll, ukuze igebe lizoqhubeka ukwanda, okuzoholela ukugqwala futhi ukuguga ipuleti ngokwalo kakhulu futhi sina, kuze kube umthelela izinga imikhiqizo iphuma.Ukugqwala kokujikeleza kwamanzi okupholisa epuleti lokugaya, kungesinye sezizathu ezibaluleke kakhulu zokugqwala nokuguga kwepuleti elijikayo.

(2) Metal fatigue wear.

Inqubo yokusebenza kwe-workshop ye-rolling mill plate ngomthelela oqhubekayo wamandla kuzo zonke izinhlangothi, i-liner ngokwayo kanye ne-liner kanye nendawo yokuhlangana ye-workshop yamapuleti kuzokhiqiza ukuguga okujwayelekile kokukhathala kwensimbi, okubangelwa izici zensimbi ngokwayo.

(3) Ubuhwaba obungaphezulu.

Ubulukhuni bobuso buthinta ngokuqondile indawo yokukhwelana phakathi kolayini nohlaka, indawo yokukhwelana engaphezulu ngemva kokucubungula umshini wokugaya cishe cishe u-50%, kanti indawo yokukhwelana ngemva kokuqedwa komshini wokugaya ingafinyelela cishe ku-70%.Njengoba indawo encane, ingcindezi enkulu endaweni yeyunithi, mfushane umjikelezo wokukhathala kwensimbi, kuba mfushane impilo yesevisi.

(4) I-Rack deformation.

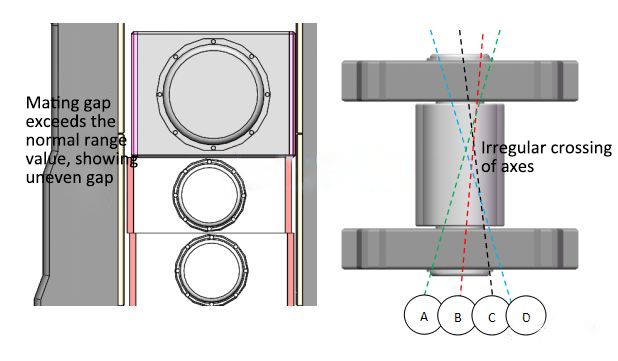

Ukuthwala isihlalo endaweni yokugaya umthelela oqhubekayo ohambisana nokugqwala kwendawo engaphezulu ye-liner, kungaholela ngokushesha engxenyeni yokusekela ye-deformation.Ngenxa yalesi sikhala esikhulayo, isihlalo sokuthwala sinikezwa inkululeko eyengeziwe yokuhamba.Ngemva kokuhlola izitebhisi eziningi zokugaya siphawule ukuthi ukwanda kwegebe lokususa akuhambisani kulo lonke ubude besitendi, negebe elikhulu lenzeka ngaphansi komugqa wokugoqa.Kukhona futhi umehluko obonakalayo phakathi kohlangothi lwe-drive kanye nohlangothi luka-opharetha.(b) Lokhu kunyakaza okweqile kuhlangene noshintsho endaweni kubangele ukuchezuka okungafuneki okuqondile, okubangele ukuphambana kwamaroli omsebenzi.

(5) Ukuxegiswa kwamabhawodi abopha ulayini ngesikhathi sokugaya.

Ama-bolts okubopha ama-liner adinga ukuhlolwa futhi aqiniswe njalo, futhi isikhathi sokuhlola esivamile kufanele kube lapho ama-rolls eshintshwa.Ngenxa yezinkinga zokuphatha imishini, ama-bolts okubopha awaqinisiwe ngokuphumelelayo nangesikhathi esifanele, i-liner plate kanye ne-mill plaque izoveza igebe elithile phakathi kwabo, ukuze ngesikhathi sokusebenza, i-liner plate ikhiqize i-pat ethile ku-plaque ngokwayo, okuholela ekutheni ukukhathala kwensimbi ebusweni be-plaque ngesikhathi esifushane, okubangela ukuguga kwe-plaque.

(6) Isiyingi esinonya.

Ukuwohloka unomphela kwendawo yesitendi sokugaya okulethwa umthwalo oqhubekayo womthelela kuzoba kubi nakakhulu ukuwohloka okubolayo kwempahla.Lapho i-liner iqala ukunyakaza, amabhawodi okulungisa azoxega futhi ahluleke ukubamba i-liner ngokuqinile kuhlaka.Lokhu kudala ithuba lama-emulsions, umusi kanye nokungcola okuvela enqubweni yokugoqa ukuze kungene ngemuva kwe-liner, ngaleyo ndlela kwandise ukusebenza kahle kokugqwala kwezinto ezingemuva kwe-liner kanye ne-paddle ngokwayo.

C, Umthelela wokugqoka kwepuleti lokugaya okukhiqizwa ngu

1. Ukugunyazwa ngokweqile.

Ngesikhathi senqubo yokugingqa, isihlalo esithwalayo seroli yokusekela, i-work roll kanye ne-liner plate epulaletini elisendaweni yokukhwelana iyakhula, kwakheka uhlobo "lwempama" kuhlaka, okuqinisa ukukhathala kohlaka, okuholela ekutheni ukusebenza okungazinzile kwemishini, ukudlidliza kunamandla.

2. Ama-roller asekelayo, i-work rollers axis cross.

Umthelela oqhubekayo wesihlalo sokuthwala endaweni yokugaya kanye nokwanda kokukhathala ebusweni besitendi kungaholela ngokushesha ekuwohlokeni kwesigaba sokusekela.Ngenxa yalesi sikhala esikhulayo, isihlalo sokuthwala sinikezwa inkululeko eyengeziwe yokuhamba.Lapho sihlola siphawule ukuthi ukwanda kwegebe lokuvunyelwa kwesitendi sokugaya akuhambelani phakathi nobude besitendi, nezikhala ezinkulu ezenzeka ngaphansi komugqa wokuginqa.Kuphinde kwaba nomehluko obonakalayo phakathi kohlangothi lwe-drive kanye nohlangothi luka-opharetha.Lokhu kunyakaza okweqile kuhlangene noshintsho endaweni kubangele ukuchezuka okungafuneki okuqondile, okuholele ekuweleni komqulu womsebenzi.

3. Ikhwalithi yeshidi elibi.

Umkhiqizo ogoqwe yilesi sigayo esiguge kakhulu uzoba nomkhiqizo weshidi onesimo esingaphezulu esingathandeki uma ukalwa, futhi ukugoqa kuzotholwa ohlangothini lobude beshidi, kunciphisa ubude obugoqiwe.Kuzothinta ubukhulu bokujiya kanye nokuma kwepuleti lomugqa wepuleti, okuzothinta umphumela wokusetshenziswa komsebenzisi ongezansi.Ukushintshashintsha kokuqina kobude nobukhulu be-wedge esigabeni esiphambanayo kungenzeka.Umumo wepuleti uzokhiqiza amaphutha amagagasi, okwenza umumo womugqa ungahambisani nomumo wepuleti eligoqiwe elivamile.Izinguquko ezinkulu ekubunjweni kwepuleti nazo zingakhiqiza ukwaliwa komshini wokugaya, okuholela ekwenyukeni kwesikhathi sokuncipha komugqa wokugaya nokusetshenziswa.

Isikhathi sokuthumela: Jan-30-2023