A, Ukusebenza okuqhelekileyoilitye lokusilaurhulumente

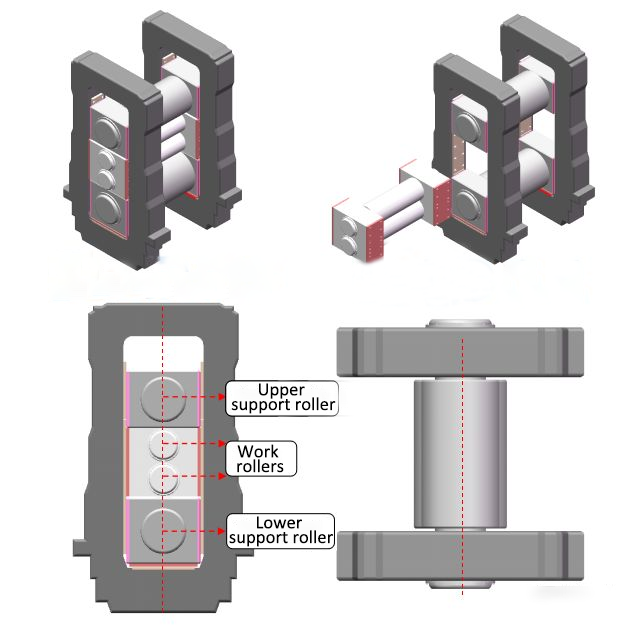

Ubungakanani befestile yepleyiti entsha yokusila buhlala bungaphakathi koluhlu lonyamezelo oluthile, ngokuqhelekileyo, ukunyamezela ubungakanani befestile buhlala kuluhlu lwe +0.3 - +0.7mm, ukwenzela ukubaumqulu wokusilaisihlalo esiphetheyo ukuseka indawo ezinzileyo nechanekileyo.

B, Indawo yokugqoka ipleyiti yokusila kwaye ibangele uhlalutyo

1. Nxiba indawo

1

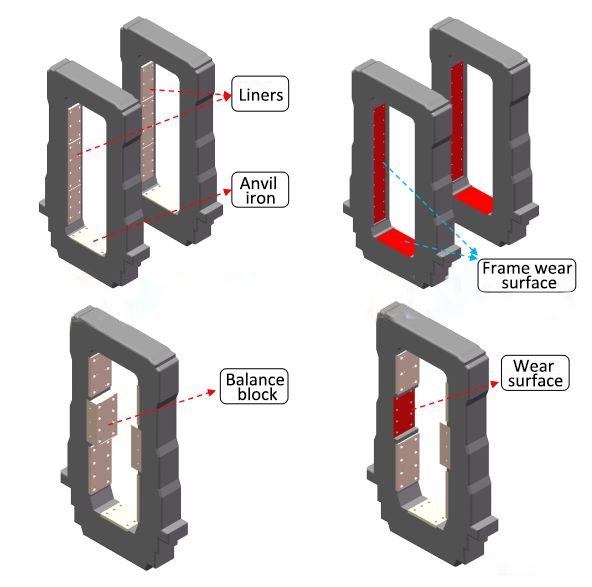

(2) Intsimbi yeanvil kunye nendawo yokukhwelana.

(3) Ibhloko yokulinganisa (okanye isixhobo sokugoba) kunye nendawo yokukhwelana.

2. Uhlalutyo lwezizathu zokugqoka i-mill plate

(1) Ukupholisa umhlwa kwamanzi.

Njengoko indawo yokukhwelana phakathi kwe-liner kunye neworkshop yintsimbi ukuya kwintsimbi, isinyithi kwinkqubo yokucubungula nokuba ifikelela kumphezulu ophezulu ngokufanelekileyo kunye nomgangatho, kodwa amacandelo amabini afanelekileyo akakwazi ukufikelela kwi-100% efanelekileyo. , okuya kubangela umsantsa phakathi kwendawo yokukhwelana.Ngethuba lenkqubo yokuvelisa, amanzi okupholisa aya kungena kwi-liner plate kunye nesithuba sokukhwelana kwendawo yokusila, amanzi okupholisa aya kubangela ukubola kumphezulu weplate yokusila, okwenza umaleko we-oxide, ukwenzela ukuba kwinkqubo yokuqengqeleka, i-liner. ipleyiti iya kubangela uxinzelelo olungqongqo kwi ekhululekileyo oxide umaleko pat, njl, ukuze umsantsa uya kwanda ngakumbi, nto leyo eya kukhokelela umhlwa kunye banxibe ipleyiti ngokwayo ngakumbi nangakumbi nangakumbi, de impembelelo yomgangatho imveliso esongwayo.Ukugqwala kokujikeleza kwamanzi okupholisa kwipleyiti yokusila, sesinye sezona zizathu zibalulekileyo zokubola kunye nokunxiba kwe-rolling plate.

(2) Ukudinwa kwesinyithi.

Inkqubo yokusebenzela icwecwe lokusila ngefuthe eliqhubekayo lamandla kuzo zonke iinkalo, i-liner ngokwayo kunye ne-liner kunye ne-mating surface ye-workshop yepleyiti iya kuvelisa ukukhathala okuqhelekileyo kwesinyithi, okubangelwa yimpawu zentsimbi ngokwayo.

(3) Uburhabaxa bomphezulu.

Uburhabaxa bomphezulu buchaphazela ngokuthe ngqo indawo yokukhwelana phakathi komgca kunye nesakhelo, umphezulu wokukhwelana komphezulu emva kokulungiswa komatshini wokusila umalunga ne-50% kuphela, kwaye umphezulu wokukhwelana emva kokugqitywa komatshini wokusila ungafikelela malunga ne-70%.Ngommandla omncinci, uxinzelelo olukhulu kwiyunithi yendawo, mfutshane umjikelo wokukhathala kwesinyithi, mfutshane ubomi benkonzo.

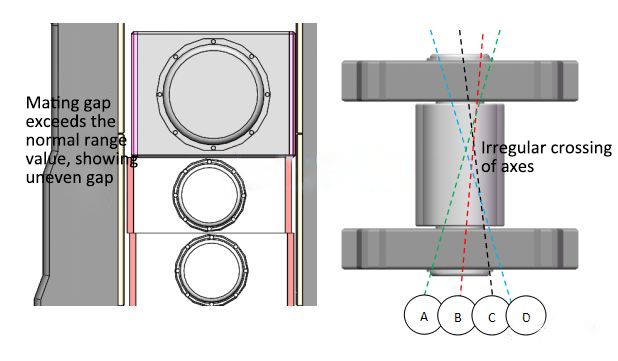

(4) Ukuguqulwa kweeRakhi.

Ukuthwala isihlalo kwi-mill stand impembelelo eqhubekayo edibeneyo kunye nokugqwala komgangatho we-liner, kunokukhokelela ngokukhawuleza kwinxalenye yenkxaso ye-deformation.Ngenxa yoku kwanda kwezithuba, isitulo sokuthwala sinikwa inkululeko engakumbi yokuhamba.Emva kokuphonononga iindawo ezininzi zokusila siye saqaphela ukuba ukwanda kwesithuba sokucocwa akungqinelani kubude bendawo yokumisa, esona sikhewu sikhulu senzeka ngaphantsi komgca wokuqengqeleka.Kukho umahluko obonakalayo phakathi kwecala lokuqhuba kunye necala lomqhubi.(b) Le ntshukumo igqithisileyo idityaniswe notshintsho kwindawo yabangela ukutenxa okungafunekiyo okuthe nkqo, okubangele ukunqumla komsebenzi.

(5) Ukukhulula iibholithi ezibotshelelwa kwisixhobo sokusila.

Iibholiti zokuqinisa i-liner kufuneka zihlolwe kwaye ziqiniswe rhoqo, kwaye ixesha eliqhelekileyo lokuhlola kufuneka libe xa ii-rolls zitshintshwa.Ngenxa yeengxaki zolawulo lwezixhobo, iibholiti zokubopha aziqiniswanga ngokufanelekileyo nangexesha elifanelekileyo, ipleyiti yomgca kunye ne-plaque yokusila iya kuvelisa umsantsa othile phakathi kwabo, ukwenzela ukuba ngexesha lokusebenza, i-plate ye-liner ivelise i-pat ethile kwi-plaque ngokwayo, ekhokelela kwi-plaque. ukukhathala kwesinyithi ebusweni be-plaque ngexesha elifutshane, nto leyo ebangela ukugqoka kunye nokukrazula kwe-plaque.

(6) Isangqa esikhohlakeleyo.

Uguqulo olusisigxina lomgangatho wokusila oluziswa ngumthwalo oqhubekayo wempembelelo iya kuba mbi ngakumbi kukonakala kwempahla.Xa i-liner iqala ukuhamba, i-bolts yokulungisa iya kukhulula kwaye ingaphumeleli ukubamba umgca ngokuqinileyo kwisakhelo.Oku kudala ithuba lokuba i-emulsions, i-steam kunye ne-contaminants ukusuka kwinkqubo yokuqengqeleka ukungena emva komgca, ngaloo ndlela ukwandisa ukusebenza kakuhle kwe-corrosion yezinto ezisemva kwe-liner kunye ne-paddle ngokwayo.

C, Impembelelo yokunxiba ipleyiti yokusila eveliswa yi

1. Ukukhutshwa ngokugqithisileyo.

Ngethuba lenkqubo yokuqengqeleka, isihlalo sokuthwala i-rolling roll, i-work roll kunye ne-liner plate kwi-plate kwi-gap yendawo yokukhwela inyuka, yenza uhlobo "lwempama" kwisakhelo, ukuqinisa ukukhathala kwesakhelo, okubangelwa ukusebenza okungazinzanga kwesixhobo, ukungcangcazela kunamandla.

2. I-roller yenkxaso, i-roller work axis cross.

Impembelelo eqhubekayo yesihlalo sokuthwala kwisigxina sokugaya kunye nokunyuka kokukhathala kokugqoka kwindawo yokuma kunokukhawuleza ukukhokelela ekuguqulweni kwecandelo lenkxaso.Ngenxa yoku kwanda kwezithuba, isitulo sokuthwala sinikwa inkululeko engakumbi yokuhamba.Sakuba sihlolisisiwe siye saqaphela ukuba izithuba ezininzi zokuvula indawo yokusila azihambelani kubude bendawo yokusila, nezona zikhewu zikhulu zenzeka ngaphantsi komgca wokuqengqeleka.Kwakhona kwakukho umahluko obonakalayo phakathi kwecala lokuqhuba kunye necala lomqhubi.Le ntshukumo igqithisileyo idityaniswe notshintsho kwindawo yabangela ukutenxa okungafunwayo okuthe nkqo, okubangele ukunqumla komsebenzi.

3. Umgangatho ophantsi wephepha.

Imveliso eqengqelekisiweyo ngolu hlobo lokusila igugile ngokugqithisileyo iya kuba nemveliso yeshiti enemeko enganqwenelekiyo yomphezulu xa ilinganiswa, kwaye i-arching iya kubhaqwa kwicala lobude beshiti, kucuthwe ubude obusongiweyo.Iyakuchaphazela ubukhulu bobungakanani kunye nokumila kwepleyiti yomgca wepleyiti, nto leyo eya kuchaphazela isiphumo sokusetyenziswa komsebenzisi osezantsi.Ukuguquguquka kobungqingqwa kubude kunye nemilinganiselo ye-wedge kwi-cross-section ingenzeka.Imilo yepleyiti iya kuvelisa iziphene zamawavy, okwenza ukuba imilo yestrip ingahambelani nokumila kwepleyiti eqhelekileyo.Utshintsho olumandla kwimilo yepleyiti lunokuvelisa ukwaliwa komatshini wokusila, okukhokelela ekwenyukeni kwexesha lokuncipha kunye nokusetyenziswa komgca wokusila.

Ixesha lokuposa: Jan-30-2023