A, Kushanda kwamazuva osechigayostate

Saizi yehwindo yeguyo nyowani kazhinji iri mukati meimwe nzira yekushivirira, kazhinji kutaura, kushivirira kwehwindo kunowanzo kuve muhuwandu hwe +0.3 - +0.7mm, kune iyochigayo rollkutakura chigaro chekumisa nzvimbo yakagadzikana uye yakarurama.

B, Chigayo chinopfeka chinzvimbo uye chikonzero chekuongorora

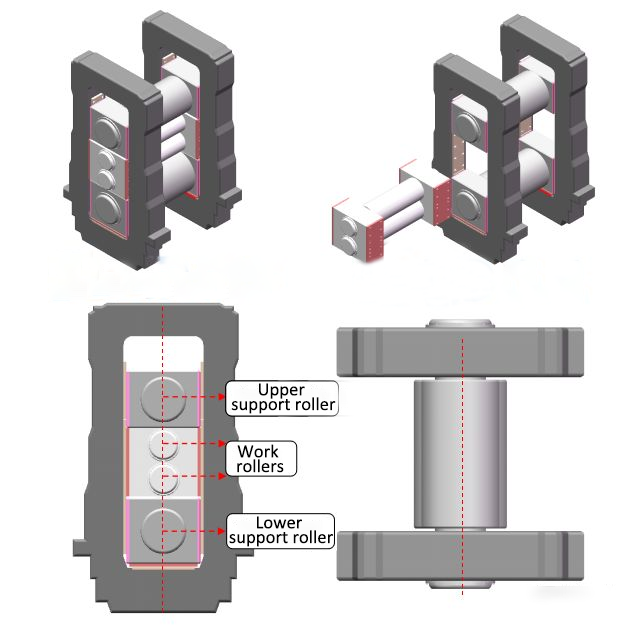

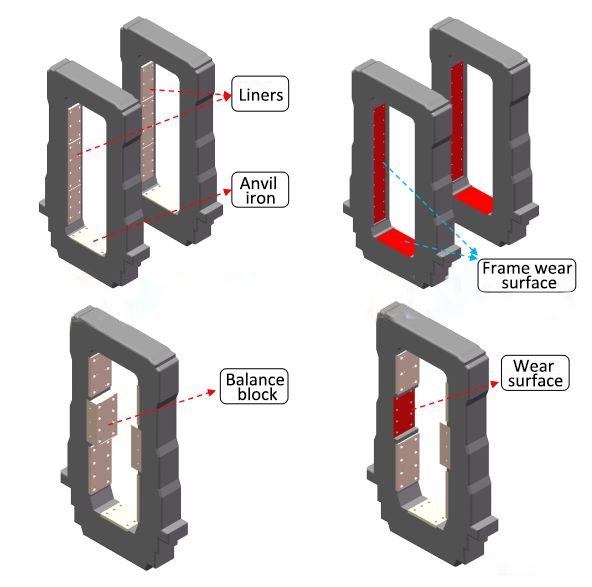

1. Pfeka chinzvimbo

(1) Iyo yepamusoro uye yepasi inotsigira rolls, yebasa roll liner uye rack mating pamusoro.

(2) Simbi yesimbi uye rack mating pamusoro.

(3) Balance block (kana bending roller mudziyo) uye rack mating pamusoro.

2. Ongororo yezvikonzero zvekupfeka kweguyo

(1) Kutonhodza ngura yemvura.

Sezvo nzvimbo yekubatanidza pakati pe liner neworkshop iri simbi-ku-metal inokodzera, iyo simbi iri mukugadzirisa maitiro kunyangwe ikasvika pakakwirira kumusoro kupedzisa uye kupfava, asi zvikamu zviviri mukukwana hazvikwanise kusvika 100% kukwana. , izvo zvinozoita kuti pave nemukaha pakati pemating surface.Munguva yekugadzira, mvura inotonhorera inopinda mundiro ye liner uye gap rekubatanidza pamusoro peguyo, mvura inotonhorera inokonzeresa ngura pamusoro peguyo ndiro, ichigadzira layer ye oxide, kuitira kuti pakukunguruka, liner. ndiro inokonzeresa kumanikidza kwakasimba pane yakasununguka oxide layer pat, nezvimwewo, kuitira kuti gaka riwedzere kuwedzera, izvo zvinozotungamira mukuora uye kupera kweplate pachayo zvakanyanya uye zvakanyanya, kudzamara kukanganisa kwemhando yezvigadzirwa zvakakungurutswa.Kuora kwekutenderera kwemvura inotonhorera paguyo ndiro, chimwe chezvikonzero zvakakosha zvekuora uye kupera kweplate inokunguruka.

(2) Metal kuneta kupfeka.

Rolling mill plate workshop operation process by the always impact of the force in all direction, liner yacho pachayo ne liner nenzvimbo yekusangana yeplate workshop inoburitsa yakajairika simbi kuneta kupfeka, izvo zvinokonzerwa nehunhu hwesimbi pachayo.

(3) Kushata kwepamusoro.

Kushata kwepamusoro kunobata zvakananga nzvimbo yekubatanidza pakati pe liner uye furemu, nzvimbo yekubatanidza pamusoro mushure mekugadzira muchina wekugaya inongosvika makumi mashanu muzana, uye nzvimbo yekubatanidza mushure mekupedza muchina wekukuya inogona kusvika pa70%.Nenzvimbo diki, iyo yakakura kumanikidza pane imwe unit nzvimbo, kupfupika kutenderera kwesimbi kuneta kupfeka, kupfupika kwehupenyu hwesevhisi.

(4) Rack deformation.

Kutakura chigaro pamill stand inoenderera inobata pamwe nekuora kweiyo liner surface, inogona kukurumidza kutungamirira kune chikamu chekutsigira che deformation.Nekuda kwenzvimbo iyi yakawedzera, chigaro chekutakura chinopihwa rusununguko rwakawanda rwekufamba.Mushure mekuongorora zvigayo zvakawanda takaona kuti kuwedzera kwegomba rekubvisa hakuenderane muhurefu hwechigayo, paine gaka guru rinoitika pazasi pemutsara wekutenderera.Pane zvakare mutsauko unoonekwa pakati pedivi rekutyaira nedivi reopareta.(b) Uku kufamba kwakanyanyisa kusanganiswa nekuchinja kwechinzvimbo kwakakonzera kutsauka kusingadiwe, izvo zvakakonzera kuyambuka kwebasa.

(5) Kusunungurwa kwemabhaudhi anosunga liner panguva yekushanda kweguyo.

Iyo liner yekusunga mabhaudhi inoda kuongororwa uye kusimbiswa nguva dzose, uye yakajairika yekuongorora nguva inofanira kunge iri iyo mipumburu inotsiviwa.Nekuda kwematambudziko ekugadzirisa midziyo, mabhaudhi ekusungirira haana kusimba uye nenguva, iyo liner ndiro uye giyo plaque inoburitsa imwe gap pakati pavo, kuitira kuti panguva yekushanda, liner ndiro inoburitsa imwe pat paplaque pachayo, zvichitungamira kuneta kwesimbi pamusoro peiyo plaque munguva pfupi, izvo zvinokonzeresa kupera uye kubvaruka kweplaque.

(6) Denderedzwa rakashata.

Iko kushanduka kwechigarire kwechigayo chekumira chinounzwa nekuenderera mberi kwekukanganisa kunowedzera kunowedzera kuipa nekuora kwekuora kwezvinhu.Kana iyo liner inotanga kufamba, mabhaudhi ekugadzirisa anosununguka uye anokundikana kubata liner zvakasimba mufuremu.Izvi zvinogadzira mukana we emulsions, steam uye zvinosvibisa kubva pakukungurusa nzira kuti ipinde kuseri kwe liner, nekudaro kuwedzera corrosion kunyatsoita zvinhu zviri kumashure kwe liner uye paddle pachayo.

C, Mhedzisiro yekupfeka kweguyo rinogadzirwa ne

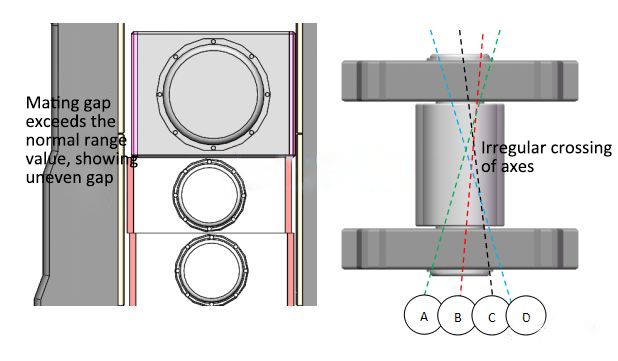

1. Kuregererwa kwakanyanya.

Munguva yekukunguruka, chigaro chekutakura cherutsigiro rwerutsigiro, roll yebasa uye liner plate pandiro pane gap repamusoro rinowedzera, richigadzira rudzi rwe "mbama" pafuremu, ichiwedzera kuneta kupera kwefuremu, zvichikonzera kusagadzikana kushanda kwemidziyo, vibration yakanyanya.

2. Kutsigira rollers, basa rollers axis cross.

Izvo zvinoramba zvichikonzera chigaro chekutakura pachigayo chegayo pamwe nekuwedzera kwekuneta kupera pamusoro pechigadziko chinogona kukurumidza kutungamirira ku deformation yechikamu chekutsigira.Nekuda kwenzvimbo iyi yakawedzera, chigaro chekutakura chinopihwa rusununguko rwakawanda rwekufamba.Patakaongorora takaona kuti mill stand clearance gap inowedzera haienderani nehurefu hwenzvimbo yacho, paine maburi mahombe anoitika pazasi pemutsara wekutenderedza.Paivewo nemusiyano unooneka pakati pedivi rekutyaira nedivi reanoshanda.Kufamba kwakanyanyisa uku kwakasanganiswa nekuchinja kwechinzvimbo kwakakonzera kutsauka kusingadiwe, izvo zvakakonzera kuyambuka kwebasa.

3. Hunhu husina kunaka hwepepa.

Chigadzirwa chakakungurutswa neichi chigayo chakasakara zvakanyanyisa chichava neshizha rinenge risingadiwe pamusoro pemamiriro kana akayerwa, uye arching inozoonekwa munzira yehurefu hweshizha, ichidzikisa kureba kwakatenderedzwa.Ichakanganisa chiyero chehukobvu uye chimiro cheplate chemutsetse weplate, izvo zvinokanganisa mashandisiro emushandisi wezasi.Kuchinja kwehukobvu mukureba uye hukuru hweweji muchikamu-chikamu chinogona kuitika.Chimiro cheplate chinoburitsa hurema hwewavy, zvichiita kuti chimiro chemutsetse chisaenderane neyakajairika yakakungurutswa ndiro chimiro.Shanduko dzakakomba muchimiro chendiro dzinogona zvakare kuburitsa chigayo chinorambwa, zvichikonzera kuwedzera kwechigayo mutsara kuderera uye kushandiswa.

Nguva yekutumira: Jan-30-2023