A, Arụ ọrụ nkịtịigwe ihe igwesteeti

Ogo mpio nke efere igwe ihe ọhụrụ na-adịkarị n'ime oke nnabata, n'ozuzu n'ikwu okwu, nha nha windo na-adịkarị na nso +0.3 - +0.7mm, makaigwe igwe mpịakọtaoche na-ebu iji guzobe ọnọdụ kwụsiri ike na nke ziri ezi.

B, Efere igwe ihe na-eyi ọnọdụ na-akpata nyocha

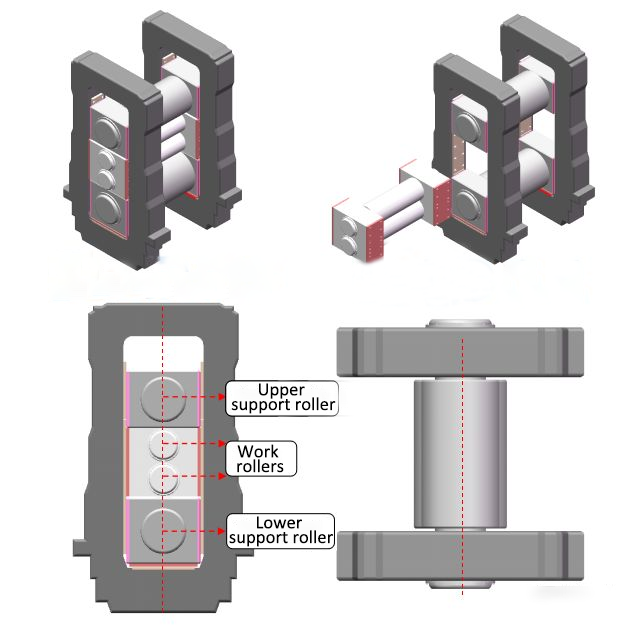

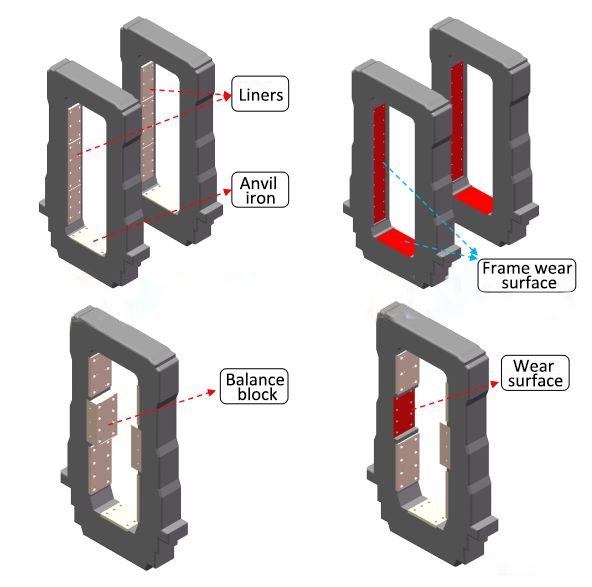

1. Yiri ọnọdụ

(1) Ihe nkwado nke elu na nke ala, akwụkwọ mpịakọta ọrụ na akwa mating elu.

(2) Iron anvil na rack mating surface.

(3) Balance block (ma ọ bụ na-ehulata ngwaọrụ rola) na rack mating elu.

2. Nyocha nke ihe na-akpata igwe igwe na-eyi uwe

(1) Ndajụ mmiri corrosion.

Dị ka mating elu n'etiti liner na ogbako bụ a metal-to-metal dabara, na metal na nhazi usoro ọbụna ma ọ bụrụ na ọ ruru a pụtara elu elu imecha na flatness, ma abụọ components na dabara enweghị ike iru 100% dabara. , nke ga-eme ka ọdịiche dị n'etiti elu mating.N'oge usoro mmepụta ihe, mmiri dị jụụ ga-abanye n'ime efere liner na ọdịiche dị n'elu mating nke igwe igwe, mmiri dị jụụ ga-eme ka corrosion n'elu efere igwe nri, na-eme ka oyi akwa nke oxide, nke mere na n'ime usoro ntụgharị, liner. efere ga-eme ka ike siri ike na rụrụ oxide oyi akwa pat, wdg, nke mere na ọdịiche ga-n'ihu na-abawanye, nke ga-eduga na corrosion na-eyi nke efere n'onwe ya na-adị njọ karị, ruo mgbe mmetụta nke àgwà nke akpọrepu ngwaahịa.Nrụrụ nke na-ekesa mmiri jụrụ oyi na efere igwe nri, bụ otu n'ime ihe kachasị mkpa maka mmebi na iyi nke efere mpịakọta.

(2) Metal ike ọgwụgwụ na-eyi.

Usoro ọrụ ogbako igwe igwe na-arụ ọrụ site na mmetụta mgbe niile nke ike n'akụkụ niile, liner n'onwe ya na liner na elu mating nke ogbako efere ga-emepụta ike ọgwụgwụ ígwè nkịtị, nke a na-eme site na njirimara nke metal n'onwe ya.

(3) Ịdị nro dị n'elu.

Ọdịiche dị n'elu na-emetụta mpaghara mating n'etiti liner na etiti ahụ, elu mating elu mgbe igwe igwe igwe na-arụ ọrụ bụ naanị ihe dị ka 50%, na mating elu mgbe egwechachara igwe nwere ike iru ihe dịka 70%.Na obere ebe, ka ukwuu na nrụgide kwa unit mpaghara, nkenke okirikiri nke metal ike ọgwụgwụ na-eyi, na mkpumkpu ndụ ọrụ.

(4) Nrụrụ n'ọkwa.

Oche na-ebu n'elu igwe igwe na-eguzo na-enwe mmetụta na-aga n'ihu yana mmebi nke elu liner, nwere ike iduga ngwa ngwa na akụkụ nkwado nke nrụrụ ahụ.N'ihi ohere a na-abawanye, a na-enye oche na-ebu ibu karịa nnwere onwe imegharị.Mgbe anyị nyochachara ọtụtụ igwe ihe igwe, anyị chọpụtara na mmụba nke oghere mkpochapụ na-ekwekọghị n'ogologo ebe a na-adọkpụ, na nnukwu oghere na-apụta n'okpuru ahịrị mpịakọta.Enwekwara ọdịiche pụtara ìhè n'etiti akụkụ ụgbọala na akụkụ onye ọrụ.(b) Mgbanwe a gabigara ókè yana mgbanwe ọnọdụ kpatara ndahie kwụ ọtọ na-achọghị, nke butere ịgafe akwụkwọ mpịakọta ọrụ.

(5) Ntọpu nke bolts na-ekegide liner n'oge ọrụ igwe igwe.

Ọ dị mkpa ka a na-enyocha ma na-agbatị bolts liner mgbe niile, na oge nyocha kwesịrị ịbụ mgbe edochiri akwụkwọ mpịakọta ndị ahụ.N'ihi nsogbu njikwa akụrụngwa, bolts ndị na-emechi emechi adịghị arụ ọrụ nke ọma na nke ọma n'oge, efere liner na plaque igwe igwe ga-emepụta ọdịiche dị n'etiti ha, nke mere na mgbe a na-arụ ọrụ, efere liner na-emepụta otu pati na plaque n'onwe ya, na-eduga ike ọgwụgwụ ígwè n'elu ihe ncheta ahụ n'ime obere oge, nke na-eme ka ọkpụkpụ na akwa akwa.

(6) okirikiri ọjọọ.

Nrụrụ na-adịgide adịgide nke igwe igwe kwụ ọtọ na-ebute site na ibu mmetụta na-aga n'ihu ga-akawanye njọ site na mmebi nke ihe na-emebi emebi.Mgbe liner na-amalite ịkwagharị, bolts na-edozi ahụ ga-atọpụ ma ghara ijide liner nke ọma na etiti.Nke a na-emepụta ohere maka emulsions, uzuoku na ihe ndị na-emerụ emerụ site na usoro mpịakọta ịbanye n'azụ liner, si otú ahụ na-abawanye arụmọrụ nke corrosion nke ihe dị n'azụ nke liner na paddle n'onwe ya.

C, Mmetụta nke igwe igwe ihe eji eyi akwa emepụtara

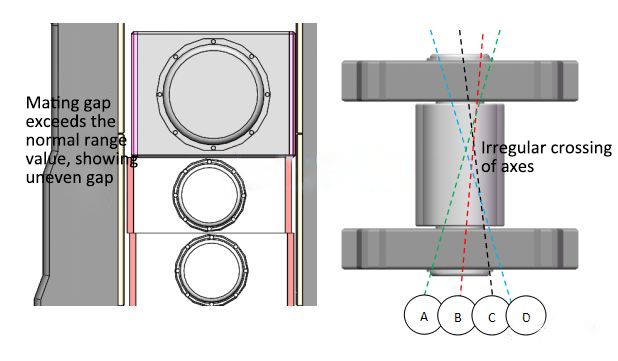

1. Oke mkpochapụ.

N'oge usoro ntụgharị, oche na-ebu nke mpịakọta nkwado, akwụkwọ mpịakọta ọrụ na efere liner na efere dị n'elu ọdịiche dị n'elu mating na-abawanye, na-etolite ụdị "ịkụ aka" na etiti ahụ, na-eme ka ike ọgwụgwụ nke etiti ahụ dịkwuo ike, na-akpata ya. arụ ọrụ na-ejighị n'aka nke akụrụngwa, vibration siri ike.

2. Nkwado rollers, ọrụ rollers axis cross cross.

Mmetụta na-aga n'ihu nke oche na-ebu n'elu igwe igwe na-agbakwunye gbakwunyere ike ọgwụgwụ na-eyi n'elu ihe nkwụnye ahụ nwere ike ime ngwa ngwa na nrụrụ nke ngalaba nkwado.N'ihi ohere a na-abawanye, a na-enye oche na-ebu ibu karịa nnwere onwe imegharị.Mgbe anyị nyochachara, anyị chọpụtara na mmụba nke oghere ihe igwe igwe kwụ ọtọ na-ekwekọghị n'ogologo ebe a na-akwụ ụgwọ, yana nnukwu oghere na-apụta n'okpuru ahịrị mpịakọta.Enwekwara ọdịiche pụtara ìhè n'etiti akụkụ ụgbọala na akụkụ onye ọrụ.Mgbanwe a gabigara ókè yana mgbanwe ọnọdụ kpatara ndahie kwụ ọtọ na-achọghị, nke butere ngafe mpịakọta ọrụ.

3. Mpempe akwụkwọ na-adịghị mma.

Ngwaahịa a na-ekpugharị site na igwe igwe na-eyi oke oke ga-enwe ngwaahịa mpempe akwụkwọ nwere ọnọdụ elu na-adịghị mma mgbe a tụrụ ya, a ga-achọpụtakwa arching n'akụkụ ogologo mpempe akwụkwọ, na-ebelata ogologo mpịakọta ahụ.Ọ ga-emetụta akụkụ ọkpụrụkpụ na ọdịdị efere nke warara efere ahụ, nke ga-emetụta mmetụta ojiji onye ọrụ na-agbada.Mgbanwe ịdị arọ n'ogologo na akụkụ wedge na mpaghara obe nwere ike ime.Ụdị efere ahụ ga-emepụta ntụpọ wavy, na-eme ka mpempe akwụkwọ ahụ ghara ikwekọ n'ụdị efere a na-atụgharị nkịtị.Mgbanwe siri ike n'ụdị efere nwekwara ike imepụta ihe igwe igwe na-ajụ, na-ebute ụbara ahịrị ahịrị igwe nri na oriri.

Oge nzipu: Jan-30-2023